The New SEW-EURODRIVE Screw Conveyor Drive Is Ready to Be Put to Work!

February 1, 2022

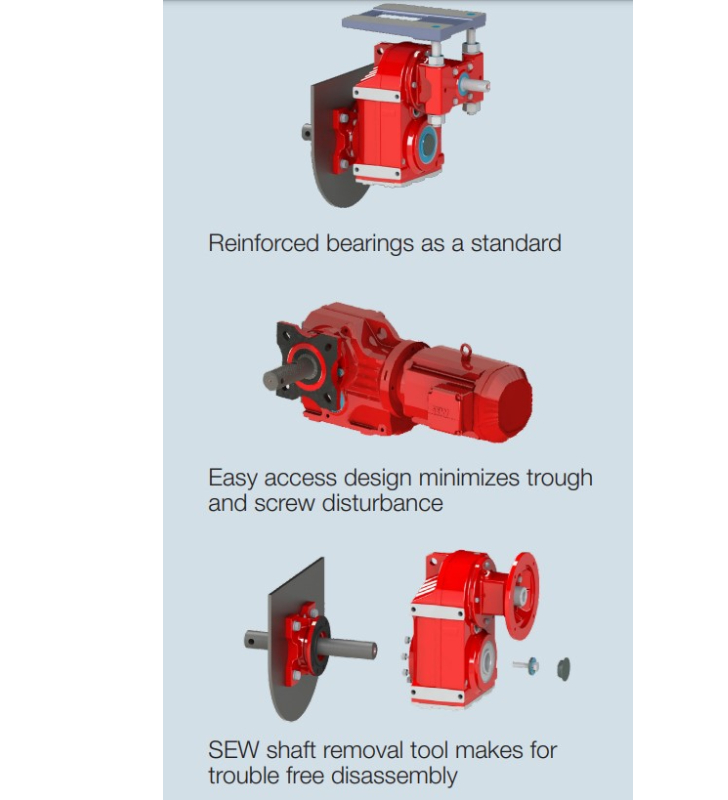

SEW’s re-designed screw conveyor now boasts a 50% higher axial load capacity, labyrinth sealing technology, and design features for ease of maintenance. Using the SEW shaft removal tool, even the most stubborn shaft can be removed with little effort. Gear unit and seal maintenance is steamlined, as the sealed CEMA flange takes the screw load while the gear unit is removed, minimizing the need for trough access and screw removal. All of these features coupled with the proven and reliable SEW gearmotor, make the new SEW screw conveyor drive an ideal solution for bulk material handling applications.

Benefits at a Glance

- •Increased L10 bearing lifetime and higher axial load capability

- •Superior sealing performance

- •Able to operate in abrasive environments

- •Reduced downtime and maintenance

- •Flexible configuration

- •Available with FAZ (parallel) or KAZ (right angle) gear units

- •Integrated gearmotor, motor platform or IEC/NEMA motor adapter

- •2 Hole or 3 Hole Shaft (stainless optional)

Download the specifications here

To learn more about the new Screw Conveyor Drive from SEW-EURODRIVE, click here