SmartD Welcomes You at Automate 2024

May 7, 2024 Visit SmartD in Booth 2476, Chicago, Il from May 6th to 9th Save the Date! Join SmartD at Automate 2024, where their team will be showcasing their cutting-edge Clean Power Variable Frequency Drives. They are excited to connect with you and discuss how their Clean Power VFDs can meet your unique automation…

Daily News

Latest Articles

Featured Article

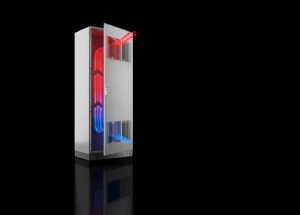

5 Benefits of the Blue e+ System

The Blue e+ introduces a new era of cooling technology, redefining cost-effectiveness and energy conservation. With speed-regulated components and patented heat pipe technology, it stands as a quantum leap in the world of enclosure climate control. Let’s explore the five key benefits of Blue e+ cooling units over traditional systems: Read more

Product News

Sponsored Content

Your Sponsored Content Here

Interested in sponsored content on Drives & Control Solutions’ homepage?

Have an idea in mind or need help getting started? We can do that.

Featured Product

Siemens Xcelerator: Scaling Roll-Out of Generative AI with Siemens Industrial Copilot

The Siemens Industrial Copilot, the generative AI-powered assistant, is now seamlessly connected to the Totally Integrated Automation (TIA) Portal. This will enable engineering teams to find the right help topic and to generate a basic visualization and code faster for programmable logic controllers (PLC). Learn more