The Most Innovative Piezomotors in the Industry

December 6, 2021

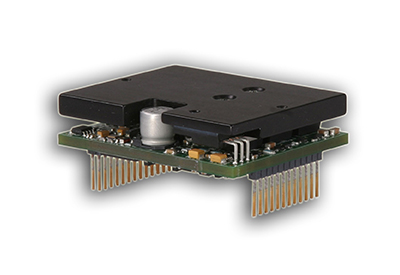

Piezo Motion’s novel series of linear and rotary piezoelectric motors represent a quantum leap in design construction of compact ultra-precision, high-performance motor technologies. Manufactured from modern lightweight reinforced engineering thermoplastics, the new range of piezoelectric motors combine superior nanometer precision with fast response at a very economical cost.

Extremely energy efficient, Piezo Motion’s motors consume zero power in hold position while still providing significant force/torque. Available in a variety of configurations including both open-loop control (non-feedback control) and closed-loop control (feedback control) systems, these motors have extremely low voltage compliance (5 to 12 Vdc) and minimal energy demands, enabling miniaturization of associated drive electronics and cost-effective pricing.

Developed and manufactured by Piezo Motion, with custom options available upon request, this new series of rotary and linear motors are rapidly finding use in a growing number of motion control applications.

Linear Motors Features:

Rapid Response Time

At 10 to 30 microseconds for a typical motion response time, the piezomotor is >100X faster than a electromagnetic motor.

Ultra High Resolution Steps

With <50 nm step resolution the linear piezomotor is capable of an incredible 20,000 steps per mm of travel.

Energy Efficient

With no command signal the piezomotor will hold position with zero power and a force >/= the maximum driving force.

Lightweight

Eliminating copper windings, magnets and ferrous laminations, enables a lightweight construction using engineering polymers.

LAS20C

- Ultra-lightweight (0.1 oz).

- Extremely energy efficient.

- Nanometer-level resolution: (<40 nm).

- Rapid response time: (10 to 30 μs).

- Low voltage with a 9 mm stroke><40nm).

- Rapid response time: (10 to 30 μs).

- Low voltage with a 9 mm stroke.

LBS004

- Extremely lightweight (0.8 oz).

- Energy efficient.

- Nanometer-level resolution: (<50 nm).

- Control step of 0.05 microns, hold force motor at 20,000 steps per mm. >0.8 oz).

LCS004 and LCS010

- Very lightweight (1.5 oz).

- Compact precision linear piezoelectric actuator.

- Energy efficient. Low voltage: {12 Vdc}, high force: {4 -10 N}, 15 mm stroke.

- Nanometer level resolution: (<50 nm).

- Rapid response time: 20μs to 30μs response compared to a typical stepper motor with 5ms to start motion.

- Open and closed loop configurations available.

Rotary Motors Features:

Applications

The series of precision motors creates applications throughout diversified industries where motion control is required.

Steps Per Revolution

With a single step size of just 10μrad at full torque, these rotary motors are capable of 625,000 steps per single rotation.

Non-Magnetic

Piezo Motion’s rotary motors provide the opportunity to operate in strong magnetic fields making them ideal applications for MRI.

Reliable

Rotary motors are available in a variety of custom designs and materials enabling applications in environments where traditional motors cannot operate.

RAS Series

- Ultra-lightweight (0.1 oz).

- Extremely energy efficient with zero energy consumption in hold position. 200,000 steps per rotation.

- Rapid response time: (10 to 30 μs).

RBS Series

- Lightweight (2.4 oz) compact precision rotary piezoelectric motor.

- Low voltage: {12 Vdc} and extremely energy efficient: zero energy consumption in hold position.

- 625,000 steps per rotation.

- Rapid response time: : (<30 μs).><30 μs). Hollow shaft and solid shaft options, direct drive with range of torques (<30 μs).

- Hollow shaft and solid shaft options, direct drive with range of torques {>>30 mN.m to >60 mN.m}.

- Yields high resolution without sacrificing the torque output.

For more information on the new line of piezo motors and encoders, visit Electromate here