A Review of ABB’s “Billions of Better Decisions”

May 16, 2022

By Krystie Johnston

ABB recently hosted Billions of Better Decisions – Empowering the Workforce with the Industrial Internet of Things, a panel moderated by Molly Wood, Climate Investor and Journalist, and Managing Director of Launch. There she interviewed three industry experts: Peter Terwiesch, President of Process Automation at ABB, Ahmed Hashmi, Senior Vice President, Digital at bp, and Michael Wade, Professor of Innovation and Strategy and Director of Global Centre for Digital Business Transformation at IMD.

Their discussion focused on the convergence of digitalization and sustainability and the critical role of the industrial IoT. This article highlights what these experts address as the mega trends of digitalization and sustainability and how leaders can use the industrial IoT to make better decisions and tackle the massive threat of the climate crisis.

These High-Level Findings are Weaved Throughout the Panelists’ Conversation

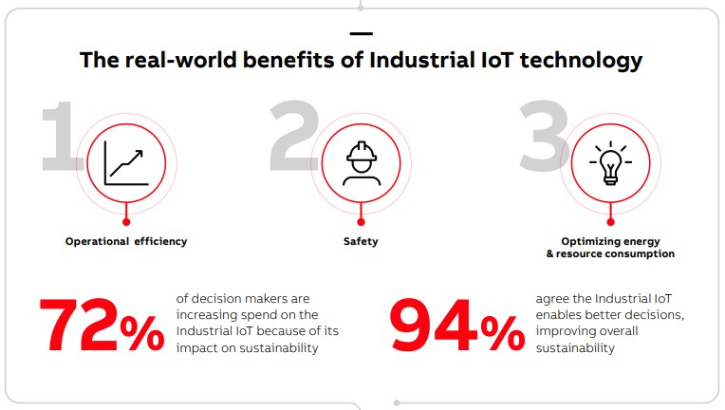

The panel was prompted by a recent global study of industrial IoT decision makers released by ABB, Industrial Transformation’s New Imperative, where several high-level findings were brought to light. In this study, ABB looked at the critical relationship between digitalization and sustainability and found that 94% of respondents agree that digitalization is essential to achieving their own businesses’ sustainability goals. It also revealed that only 35% have implemented industrial IoT at scale. Additionally, 72% of companies are increasing investment in industrial IoT specifically to address sustainability aims. And finally, the study showed that perceived cyber security vulnerabilities are the number one barrier to improving sustainability throughout the industrial IoT.

Digitalization and sustainability are mega trends in industry today. The global pandemic has made the world pause and think more about these trends, as have current events in Europe and new reports on the environment like the one from the IPCC. While the world combats growing challenges, it is becoming more evident that the industrial IoT can help organizations make better decisions. Companies and individuals are feeling pressure to perform while balancing protection of the climate. They need clear lines to be drawn with respect to what they can do to develop and implement their sustainability goals and they need tools to help them do that.

Many Companies are Setting Aims and Developing a Plan Using Existing Technologies

For instance, bp has set an aim to be a very different kind of energy company by 2030, one that delivers integrated energy solutions to their customers. This has required a reinvention of the company, as Hashmi explains, “We call this “reimagining energy” and when we came up with this idea, it required a reinvention of bp. We gave ourselves a new purpose, a net zero ambition, a strategy and sustainability frame, as well as a new financial framework and investor proposition. Of course, the focus now has moved on to executing this strategy, and this is where I like the topic of today’s panel which is around the linkages between digitalization and sustainability, because there are many and digitalization is a key enabler.”

An example will help explain how the tools and technologies in place today can help improve sustainability. During the panel discussion, the representatives from both ABB and bp talk about methane emissions. Methane gas is a potent chemical with greater heat trapping potential than CO2. Reduction of these emissions will have a considerable positive impact on the world. Technologies existing today can reduce emissions and improve operating efficiency – a clear example of how digitalization and sustainability can intersect – and an example that is both good for business and good for the environment. “There are technologies that we have today that we developed with something other than sustainability in mind, that can really have an impact” ABB’s Terwiesch notes.

Analyzers, sensors, GPS signals, and drones all help to mitigate methane leakages and are all tools that are available today. They may have been designed with performance in mind, but they can be used towards sustainability goals as well. Wade knows that successful organizations are good at integrating digital technologies into a broader organizational and cultural transformation. His work explores ways to improve innovation and creativity, leading effectively in a digital age, and the link between digitalization and ethics. He points out that,

“There are all kinds of ways that digital tools and technologies today can both improve – we do not have to give up improving our performance – but they are also helping the planet. And this is a new mindset that we are seeing, forward thinking, forward-looking companies adopting today.”– Michael Wade, Professor of Innovation and Strategy and Director of Global Centre for Digital Business Transformation at IMD

Managing the Data

These digital tools and technologies not only improve performance and the planet, but they also come with a lot of data. The volume of data that is available is something that technologists did not anticipate a few years ago. It has great potential to become a tool that companies can use to create solutions. For example, Hashmi describes how the data collected from methane reduction is helping bp to make better decisions.

He says, “Today we are moving two billion data points each day from our field operations into our central database. I would not have imagined this a few years ago. I would have thought we would get to a few million. And that data is contextualized, it is organized, and it is the life blood of decision making. So, I am quite excited about the future, I think the technologies are there, I think the will is there, to invest, the capability is there; it is about prioritizing these investments and about making them stick across the company.”

Harnessing the Industrial IoT

ABB’s report is a step in the right direction in pointing the way for organizations in harnessing the industrial IoT. Terwiesch maintains education is a key component. Only a generation or two ago, people trained for one job and did that for their entire career; but today, people need to update themselves often to avoid being outdated. Terwiesch sees companies as having an obligation to train and support their workforce, to facilitate this evolution, and to contribute back into academia thus optimizing these rapidly evolving solutions. He thinks it is important to keep up with the development of technology – and that this is another aspect of sustainability. Obviously, a decade or two ago, no one anticipated that the technologies that were developed to enhance performance or efficiency would be applicable to sustainability as well. Or that the amount of data from these technologies would be vital to making better decisions. Transparency of data is critical to this evolution; however, this practice comes with inherent challenges such as partisanship and security.

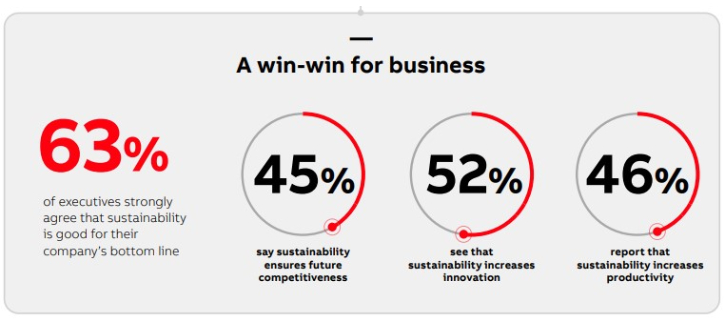

These challenges will be worked out on a global scale. The report notes that future competitiveness, efficiency, and reputation are big drivers for companies. The panelists agree that having this data will help everyone make better decisions. However, with transparency of this data, there is nowhere to hide – so the questions are, how can organizations balance transparency with the desire to hide bad news? How will the data be organized and contextualized? Who should have access? Wood asks this question to Hashmi, who mentioned earlier that this data is the life blood of decision making.

Hashmi says, “I think if we look at the state of hardware today, [it] has far achieved the vision that we laid out years ago. What is needed now is this ability to assemble these disparate data bits and make sense of them.” – Ahmed Hashmi, Senior Vice President, Digital at bp

He mentions that safety is an area where data is not hidden because it has been made personal and imperative. It is the right thing to do. He continues, “In sustainability, I do expect that once the data are reliable, sharing will improve. And I think that is where some work is needed to integrate these disparate data sets and create actionable insight. There is a lot of unactionable insight out there right now. You get data and you are swimming in it. I think this next wave must be not so much about kit and hardware, it must be about integration of data, and it must be about really accessing knowledge. And I do not mean AI and machine learning, that is high-level, what I mean is simply good contextualization of data that can equip our people to make better decisions. And it is happening, it is happening in places; it has not really joined up the 21st century corporation yet, but that is my hope and vision, that we will be, not before too long.”

Transparency of Data

Of course, the data was not initially collected with the purpose of improving the planet, so there is work to do – even to the existing data, let alone collecting new data – to help people and automation make better decisions toward sustainability. New priorities need to be set; new algorithms need to be developed. Wood questions if the data will be shared, and if drawing insights from the data is the next crucial step.

Wade agrees that it is. There is a lot of data available, and it holds a wealth of insights. He says, “The more we share the data and learn from each other, the better the impact is going to be for all of us and the planet. Organizations need to put aside their traditional competitiveness, and, for the greater good, share data in a responsible way that can help the planet.” This will require compromises to be made – both as consumers and as organizations – and there will be tradeoffs between what is best for performance and what is best for the planet.

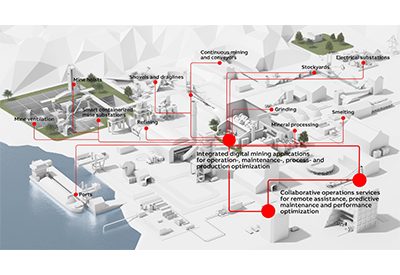

Terwiesch sees the potential for transformation as dependent on connecting systems and people to look at the data together and provide expertise remotely—not just in writing better algorithms. He says,

“I am convinced that as this further matures and as the reporting becomes more consistent, more streamlined, with well agreed standards, I think this visibility and transparency will lead to more accountability and lead to more speed and driving issue resolution.” – Peter Terwiesch, President of Process Automation at ABB

ABB’s report indicates that companies are acting. Bp, for example, is leading by example in transparency. As Hashmi observes, the company has launched a massive reinvention and sustainability framework to achieve their set aims. He knows that the boards of companies want to stay relevant in the future and are looking at holistic, balanced performance metrics. He believes it is the job of technologists like Terwiesch and himself to ensure that companies have the right wiring and capabilities to fuel that transparency.

Where Decisions Are Made

This brings up an important point about where decisions are made. Wood reflects on a recent panel she conducted with chief sustainability officers who, over the last few years, have started coming together and breaking the silos that previously blocked them in their separate divisions. She questions, “Is it enough to say, ‘this is obvious – we all have to be on the same page’?”

Wade answers, “You have sustainability and digitization. Managing the governance around that is not a trivial task; it takes real effort and energy for organizations. It requires a lot of cross bridging between different groups and departments, breaking the silos as we talked about before. Some of the heavy lifting that must happen; people need to talk to each other that do not normally talk to each other – and agree. And this is not easy.”

Looking ahead, actions that an organization can take towards digitalization and sustainability today are to make them a priority and set a clear direction. Using digitalization for energy and resource efficiency, as well as introducing renewable energies to create combined process power management are additional steps that energy intensive industries can take. Take stock of where you are in terms of your capabilities in digital and make the connections required to implement your strategy. And finally, invest in people and in partnerships. We are all in this together.

To learn more about ABB’s Billions of Better Decisions research, visit https://global.abb/topic/ability/en/better-decisions

According to Darwin’s Origin of Species, it is not the most intellectual of the species that survives; it is not the strongest that survives; but the species that survives is the one that is able best to adapt and adjust to the changing environment in which it finds itself. – Leon C. Megginson