Videos

-

Decentralized Drives for Logistics Tasks – SEW-EURODRIVE

July 15, 2024

The Klosterbrauerei Andechs has installed a new returnable glass line. Watch this video to find out how this has increased production capacity while minimising the use of resources. With 70 decentralised MOVIGEAR® performance drive units from SEW-EURODRIVE, state-of-the-art, energy-efficient technology has been installed in the traditional brewery.

This project was the first system with decentralized technology from SEW-EURODRIVE to be installed for a brewery customer in Germany.

More Information

Related Story

Why Choose SEW-EURODRIVE VFD’S?

SEW-EURODRIVE’s decentralized drive technology has everything you need – compact drive units, decentralized inverters and motion controllers for field use – and everything can be easily combined and recombined as required. This is all possible because the standardized control and communication architecture forms the perfect pairing!

-

Siemens’ SIRIUS 3RV2 Circuit Breakers

July 15, 2024

Siemens’ SIRIUS 3RV2 Circuit Breakers

SIRIUS Control from Siemens offers the largest available switching device portfolio in the market. A completely new generation of circuit breakers, contactors, overload relays and load feeders in seven sizes up to 250 kW is ready for use. The benefit of the modular system lies in its modular set-up of the components across all sizes. Everything fits together!

More Information

SIRIUS Control for controlling and protecting

Related Story

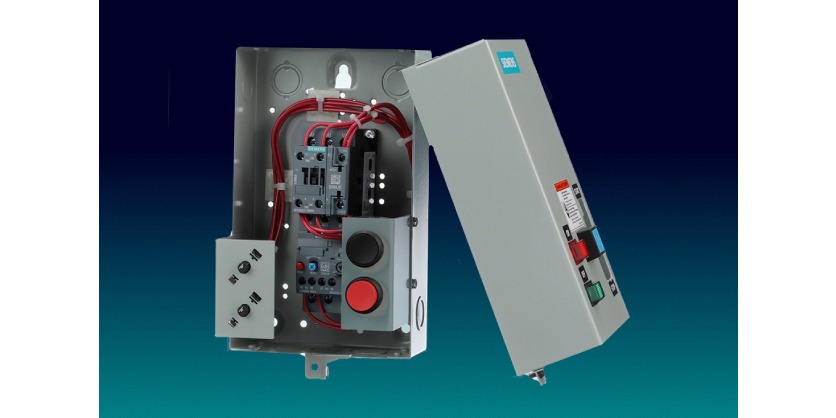

SIRIUS Motor Starters for Industrial and Construction Applications

Siemens has developed an innovative enclosed line of motor starters using their SIRIUS product family, placing the most advanced motor control technology “in a box.” To compliment their long standing “V” series made-to-order SIRIUS Motor Starters, the 3RE41 line offers a modular approach to ordering and configuring enclosed motor starters.

-

BASF Makes Digital IMPACT for Remote Visibility into Operations | Schneider Electric

June 27, 2024

BASF, perhaps the largest chemical company in the world, gains operational insights, improves visibility into individual asset health, and monitors electrical distribution with Schneider Electric Services.

More Information

Related Story

EcoStruxure Automation Expert V23.0 – Evolving Everything in the Enterprise

Schneider Electric has launched EcoStruxure Automation Expert V23.0, an open platform that connects everything in the enterprise, for the Canadian market. EcoStruxure Automation Expert is an open, IoT-enabled, plug-and-play, interoperable architecture and platform. It is universalizing automation in homes, buildings, and data centres to infrastructure and industries – and it continues to evolve.

-

The Modular Decentralized MOVI-C® Automation System | SEW-EURODRIVE

June 27, 2024

Quick and easy startup, independent of the bus system selected, with maximum flexibility. SEW-EURODRIVE meets the highest demands with their decentralized MOVI-C® modular automation system. For more information on thier drive technology, visit website www.sew-eurodrive.ca

Related Story

MOVI-C® Modular Automation System from SEW-Eurodrive

MOVI-C® is the all-in-one solution for automation tasks. Whether you want to implement standards-based single-axis or multi-axis applications, particularly complex motion control applications or customized automation solutions, MOVI C® can help you do all that and give you the scope to achieve optimum automation for new projects. This end-to-end solution from a single manufacturer covers all your needs – planning, commissioning, operation and diagnostics software, electronic control and monitoring devices, mechanical drives and gearmotors. There is only one place you must go to for all the automation components you need. Naturally, all components can be fully integrated into all automation concepts, fieldbus topologies and network standards.

-

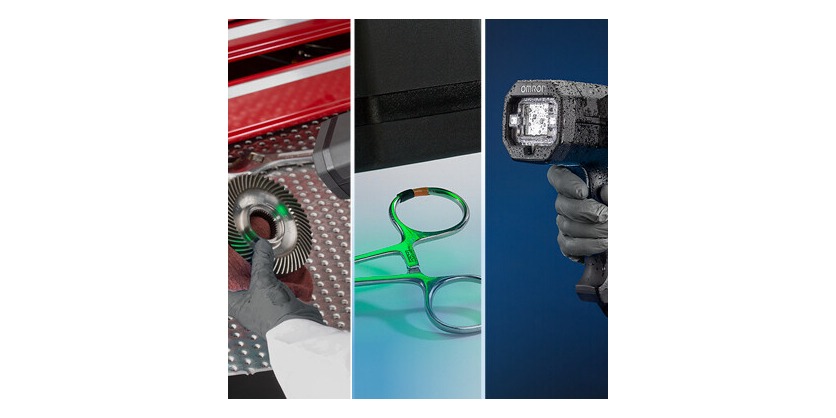

AI Enables Machines to Understand the World Around Them!

June 18, 2024

Our factories are stepping into the future with AI based sensor technology and machine learning. Ralf Gitzel, Principal Scientist at ABB explains how information and insights gained by sensors and advanced machine learning is integrated in ABB’s customers’ solutions and products.

More Information

Related Story

AI Upgrade to ABB Energy Management System Optimizes Industrial Energy Efficiency

ABB launches ABB Ability™ OPTIMAX® 6.4, the latest version of its flagship digital energy management and optimization system, to provide coordinated control of multiple industrial assets and processes, for improved energy efficiency, to reduce emissions and support decarbonization.

-

Explore EvoPacT™ ANSI Digital Circuit Breakers in 60 Seconds | Square D™ by Schneider Electric

June 18, 2024

Learn about EvoPacT™, Schneider’s latest natively digital Vacuum Circuit Breaker for Medium Voltage Power distribution applications.

Based on long and worldwide experience, this innovative new VCB has been uprated to withstand 30,000 operations making it the most sustainable and durable in its class. Coupled with state-of-the-art digital integration to transform power system applications.

Packed with Active connectivity and IIoT technology, EvoPacT™ will help you with digital transformation goals. Re-imagine all of your day-to-day task by using digital features to operate and maintain with added safety, durability, and power reliability. EvoPacT comes with access a Digital Logbook of paperless documentation. Together with the latest condition monitoring, EvoPacT can be upgraded with digital service plans to help you move towards predictive maintenance, saving time and money.

More Information

Schneider Electric’s EvoPacT ANSI Digital Circuit Breakers

Related Story

Schneider Electric Launches Digitally Enabled SureSeT Medium Voltage Switchgear in Canada

Schneider Electric has announced the upcoming launch of its new SureSeT Medium Voltage (MV) switchgear offering for the Canadian market. This new and improved solution backed by the innovative and award-winning EvoPacT circuit breaker, has been designed to address the needs for primary switchgear applications with a smaller, stronger, and smarter solution capable of managing digital day-to-day operations.

-

Introducing ABB MV Titanium, World’s First Medium Voltage, Speed-Controlled Motor

June 11, 2024

ABB’s MV Titanium concept is the world’s first medium-voltage (MV), speed controlled, industrial motor, in the 1-to-5-megawatt (MW) range that brings connectivity and control features in an easy to specify and install package. The all-in-one concept brings the benefits of energy efficiency to MV motor-driven processes, which today account for 10% of the world’s electricity. The next-generation concept has been built on ABB’s 140 years of motor design and 50 years of drives technology experience to create a solution that integrates energy efficiency, controllability, and connectivity into a single package.

More Information

Learn more: https://new.abb.com/motors-generators…

Related Story

ABB Creates World’s First Medium Voltage, Speed-Controlled Motor Concept, Facilitating Industry’s Contribution to a Low Carbon World

ABB’s MV Titanium concept is the world’s first medium-voltage (MV), speed controlled, industrial motor, in the 1-to-5 megawatt (MW) range that brings connectivity and control features in an easy to specify and install package. The all-in-one concept brings the benefits of energy efficiency to MV motor-driven processes, which today account for 10% of the world’s electricity.

-

Blue e+ Cooling Units At a Glance

June 4, 2024

Energy costs account for almost 50% of the total cost of a cooling unit, making it the area of greatest potential savings. Rittal’s “Blue e” technology can save you up to 45% in energy costs over the life cycle of the cooling unit.

“Blue e” technology highlights:

- save up to 45% in energy consumption with the same cooling output.

- Eco-mode control: The evaporator coil fan turns off as necessary, depending on the internal temperature of the enclosure.

- with components such as fans and compressors running at their optimum operating point, items in the enclosure and cooling units have a longer service life.

More Information

Related Story

Learn How You Can Improve Your Climate Control Efficiency by Upwards of 90%

Rittal’s solutions expert will work diligently to connect you with the nearest partner who can assist in creating a customized solution tailored to your specific needs. Whether it’s enhancing productivity, minimizing downtime, or optimizing your technology, Rittal is committed to streamlining your journey to efficiency. Trust them to be your reliable partner in success.

-

Telecontrol Basics |The WAGO Telecontrol Configurator

June 4, 2024

In this WAGO tutorial they will show you, which WAGO hardware can be used to establish communication in the telecontrol protocols IEC60870, IEC61850 and DNP3, which licenses are required, and which software is needed.

More Information

Related Story

SMD PCB Terminal Blocks from WAGO

Reduced to the essentials, WAGO’s new 2065 Series SMD PCB Terminal Block provides the industry’s greatest termination capability in an ultra-compact footprint. Just 2.7 mm (1.063 inch) tall, the compact 2065 Series accommodates conductors from 24 to 18 AWG (0.2 … 0.75 mm², solid and fine-stranded).