Videos

-

Circularity and Eco-Design at SEW-EURODRIVE

June 2, 2025

Circularity and Eco-design

Attractive products in all three dimensions: technical, economical and ecological

SEW-EURODRIVE has always been committed to good eco-design: Durable and efficient products, easy to repair with first-class services that extend service life, all from a modular system and worldwide. Based on their experience over the past decades, they are taking an even more systematic approach to the topic in order to continue to improve and are firmly anchoring eco-design in their processes.

More Information

Related Story

SEW-EURODRIVE – Unstoppable, Integrated, United

Since the start of SEW-EURODRIVE nearly 100 years ago, the importance of being aligned with the needs of the market and the customers it serves has remained their focus. The quality of products and a consistent and timely supply have helped make them a trusted manufacturer of gearmotors, drives, and modular systems. Their passion for technology has served them well over the years: new products designed and manufactured, the adoption and creation of technology and solutions for industry, as well as steadied expansion in the face of challenges. Driving the world is what they do.

-

Elevate Your Network Resilience with Moxa’s EDS-4000/G4000 Series

June 2, 2025

Discover the power of Enhanced Security, High Performance, and Unyielding Reliability with Moxa’s cutting-edge switches. These solutions are your pathway to a futureproof network—designed to meet the evolving demands of today’s industrial automation landscape. Embrace the future with confidence and build stronger, more resilient connections.

More Information

Moxa’s Layer 2 managed switches

Related Story

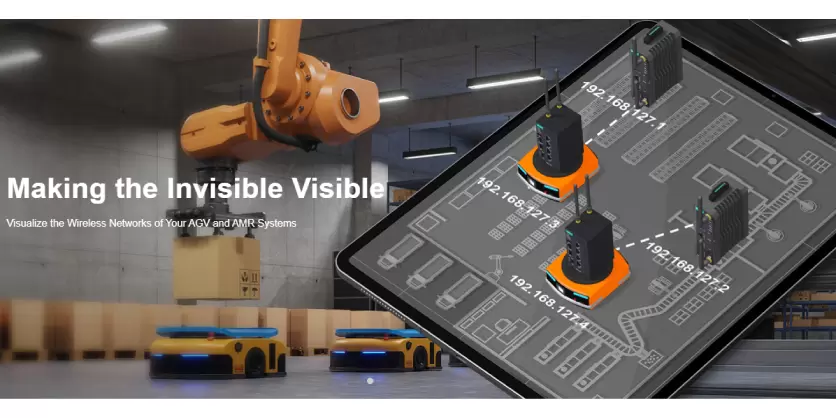

Visualize the Wireless Networks of Your AGV and AMR Systems with MOXA Solutions

As the demand for automated material handling (AMH) systems continues to rise—driven by the expansion of e-commerce and smart factories—the importance of stable wireless networks in autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) has never been more significant. With AMRs projected to grow at a CAGR of 43%* and AGVs at 24%* from 2022 to 2027, uninterrupted operations for these mission-critical systems are paramount.

-

Panduit Expands Broadband Fiber to the Home

May 30, 2025

With Panduit Fiber to the Home solutions, including pedestals, fiber drop cable assemblies, and multi-port service terminals, you can have confidence in your outside plant network.

Panduit offers an expansive Outside Plant Portfolio including fiber to the home that supports last mile network connectivity required to provide access from closest serving nodes to end user locations.

Inclusive of Multiport Service Terminal (MST), Outdoor Fiber Pedestals, and Fiber Drop Cable Assemblies, this solution is tailored for residential and commercial settings where fast and stable internet service is a must.

More Information

Related Story

Panduit Boosts PDU Offerings with Worldwide Release of G6 Series

Panduit, a global leader in innovative electrical and network infrastructure solutions, is pleased to announce the global release of its G6 PDU Series. The innovative G6 line marries the best-in-class form factor of the G5 Series with an upgraded intelligence card to bring faster performance along with new functions and cybersecurity improvements to customers.

-

RS – Supporting Your Business from End-to-End

May 28, 2025

RS – supporting your business from end-to-end. From procurement solutions to inventory management, maintenance to health and safety, RS UK and Ireland are here to help your business thrive. They’ve got the products and solutions to help you focus on what matters.

Get in touch, and see how they can make your processes more efficient and cost effective today:

Related Story

RS – and IMI Make Pneumatic Motion Control Quick, Easy, and Economical

Their portfolio of IMI pneumatic actuators for industrial and process automation applications includes IMI Bimba Original Line® cylinders, which are quick, easy, and economical to replace and offer more sizes and options than comparable solutions.

-

The Smart QO Panel Solution | 90 Sec | Schneider Electric

May 20, 2025

The Smart QO Panel Solution from Schneider Electric. The simple path to automation, monitoring, and control at the circuit level where and when you need it.

More Information

Related Story

Schneider Electric Delivers Energy Management Products and Solutions in Canada

Canada is undergoing an energy transition to become more sustainable, reduce emissions, and reach net zero targets. Wiser Energy from Schneider Electric is an integral Energy Management System that monitors devices and energy usage in real-time, helping you use electrical energy more wisely in your building.

-

New Generation of MOXA x86 Industrial Computers | ManuAuto

May 20, 2025

Moxa introduces a new generation of BXP, DRP, and RKP Series industrial computers that are specifically designed to facilitate rapid system development with reliable, adaptable, and cost-effective computing solutions.

More Information

Discover more details about BXP/DRP/RKP Series

Related Story

Made to Last, Made for You: MOXA New-gen x86 Industrial Computers

Moxa introduces a new generation of BXP, DRP, and RKP series industrial computers designed to facilitate rapid system development with reliable, adaptable, and cost-effective computing solutions. The industrial computers are based on a pre-formulated configure-to-order architecture, making it easy to meet various system development and integration requirements. Their wide-temperature design and fanless operation ensure stable performance even in harsh environments. Furthermore, a 3-year warranty and 10-year product longevity underscores our commitment to product quality.

-

Hammond Power Solutions’ Capabilities

May 6, 2025

This video highlights Hammond Power Solutions’ complete product capabilities and the industries that they serve.

HPS is one of the largest manufacturers of dry-type transformers in North America. They engineer and manufacture a wide range of standard and custom transformers that are exported globally in electrical equipment and systems. They support solid industries such as oil and gas, mining, steel, waste and water treatment, commercial construction, data centres and wind power generation.

HPS leads the industry in these markets through its technical design strength, breadth of product, and manufacturing capabilities, making HPS a stronger company both fundamentally and financially.

Company Profile

They have developed a reputation as one of the most capable and broadest manufacturer of dry-type magnetics in the world. Their products can be found on every continent, every ocean and have even orbited in space. Their engineering database contains over one million designs ranging from the smallest control transformers to the largest dry-type transformers ever manufactured. Their customers have come to rely on them for support at the most critical stages of their needs. Their stability and integrity as a supplier are paramount in an industry where demands must be resolved quickly and effectively. HPS has grown to become the largest dry-type transformer manufacturer in North America.

For over 100 years, HPS has grown from a small family-owned business in the shortwave radio market to the industry leader in magnetic transformer design and manufacturing. HPS now has multiple manufacturing facilities throughout Canada, United States, Mexico, and India. HPS currently has 9 regional warehouses throughout North America. HPS is well positioned for growth and has several long term and short term plans to continue on this path of success.

As North America’s leader in the dry-type transformer industry, we have every intention of staying there and getting stronger.

Sustainability

At Hammond Power Solutions, their passion for sustainability ensures that the world is energized today and for future generations to come. Learn more about HPS’ commitment to sustainability here.

Global Presence

Hammond Power Solutions (HPS) was established in 1917 and has continued to grow as the North American stand-alone leader for the design and manufacture of high quality custom electrical dry-type transformers and related engineered magnetic devices. The company is also a significant producer of standard products that are built to industry wide specifications.

With 9 warehouses throughout Canada and the United States, this allows us to ship standard stocked product to 90% of their customers for delivery within 48 hours of receiving a purchase order.

HPS, with its headquarters in Guelph, Ontario, Canada, operates out of seven facilities: Guelph, Ontario; Walkerton, Ontario; Baraboo, Wisconsin; Monterrey, Mexico; Compton, California; Granby, Quebec.

More Information

Related Story

Hammond Power Solutions Awarded Top Spot in 2024 TSX30 Ranking

Hammond Power Solutions Inc. (“HPS”) (TSX: HPS.A) a leading manufacturer of dry-type transformers and power quality solutions, announced the recognition as the top-performing company in the 2024 TSX30 ranking, highlighting the top-performing companies on the Toronto Stock Exchange.

-

Hammond Manufacturing Corporate Video

May 6, 2025

Customers that require unmatched performance, a large assortment, and durability in power distribution, racks, and enclosures have trusted the Hammond name for over a century. Today, Hammond Manufacturing is a global enterprise with customers all over the world.

In 1916, the company began in a backyard workshop in Guelph, Ontario, Canada. The original company, O.S. Hammond and Son, was founded in Guelph in 1917. Between 1919 and 1927, O.S. Hammond and Son began producing tube radio sets, battery chargers, and other related devices.

To accommodate the booming broadcast and communications industries, Hammond was the first business in Canada to create a range of 2-post racks and a narrow cabinet in the early 1930s. During the 1950s and 1960s, the rising demand for electrical products presented several chances for new products and diversification. Hammond quickly became a significant provider of transformers, racks, cabinets, and enclosures for the electrical and electronic industries.

Hammond has shifted its concentration to the United States and worldwide markets throughout the previous four decades. Hammond completed several key transformer acquisitions and grew to become one of the significant magnetics providers to the North American electrical OEM market. It has also forged strategic agreements with companies in the United States and Europe to expand its extensive range of enclosures and related accessories.

The Hammond Transformer Division was spun out into a new company, Hammond Power Solutions, Inc. (HPSI), in 2001. HPSI manufactures custom and catalogue transformers and associated magnetics. Both companies were free to pursue their strategic goals independently after the reorganization. Hammond Manufacturing’s primary products include electrical and electronic enclosures, racks and cabinets, power bars, and electronic (low-voltage) transformers.

Hammond Manufacturing is now a global enterprise with customers all over the world. Their 700-strong staff works together to ensure they deliver their promise of high-quality products and exceptional service. Their reputation for quality is enhanced by high-performance manufacturing equipment and continuous improvement management approaches. A significant company focus is on continuing to differentiate ourselves through high service and client satisfaction levels. These are the pillars on which their future prosperity will be built.

Hammond is based in Guelph, Ontario, Canada, and is a publicly-traded corporation on the Toronto Stock Exchange (HMM.A). Hammond has offices in Canada, the United States, the United Kingdom, and Taiwan. Hammond provides a wide range of standard products, product customization services, and technical support to electrical and electronic manufacturers, utilities, and institutions through a global network of agents and distributors.

More Information

Related Story

Hammond Manufacturing Announces Partnership with Tech-Reps to Expand Rack Mounting Solutions Representation

Hammond Manufacturing (www.hammfg.com), a global leader in enclosure and rack mounting solutions, is pleased to announce its new partnership with Tech-Reps (www.tech-reps.net), a premier manufacturers’ representative firm based in Omaha, Nebraska. This collaboration will enhance Hammond’s presence across Missouri, Southern Illinois, Kansas, Nebraska, and Iowa by leveraging Tech-Reps’ extensive industry expertise and regional market knowledge.

-

Panduit Corporate Overview

April 22, 2025

Panduit, a global leader in electrical and network infrastructure solutions, thrives on ingenuity and enterprise. They focus on solving problems and achieving success through their comprehensive portfolios, helping organizations navigate digital, electrical, and workforce transformations for sustainable growth. Customer needs are at the core of their strategy, ensuring their R&D investments lead to continuous breakthroughs in business-continuity products.

Their unwavering commitment to customer success ensures exceptional solutions and seamless support worldwide. With a dedication to innovation, extensive global presence, and deep industry expertise, they deliver tomorrow’s solutions today. Panduit is making the connections that matter.

More Information

Visit their website to find out more and learn about them

Related Story

Panduit: Embracing the Digital Economy Through Innovation and Sustainability

Panduit’s digital lives create an enormous need for power to keep us connected, and the ever-increasing tech-driven economy places increasing demands on the infrastructure responsible for the processing and analysis of digital information. Additionally, business customers are looking for more sustainable options as our digital footprint continues to grow.

For almost 70 years, the company has developed innovative infrastructure solutions to enable customers to stay connected and to help them on their sustainability journey.

-

ABB Installation Products: Made in Canada

April 21, 2025

ABB Installation Products: Made in Canada

Proudly powering Canada with 80% locally made products! Watch how ABB Installation Products sup-ports innovation, jobs, and sustainability across the country.

More Information

Related Story

Shaping the Future of Manufacturing: ABB’s Investment in Automation and Growth

During a recent visit to ABB’s facility in Pointe-Claire, dubbed T-CAN after its location alongside the Trans-Canadian highway, Elle Bremmer, Managing Editor at Kerrwil Media Ltd. saw firsthand how automation is shaping the future of manufacturing. Specializing in plastic injection molding, the plant produces key products for ABB, such as their Marrette wire connectors, NuTek thermoplastic boxes, and Carlon plastic fittings, with impressive speed and precision.