The new Danfoss ADAP-KOOL Case Controls Solution

January 27, 2020

The new Danfoss ADAP-KOOL Case Controls Solution for food retail applications drives down cost and takes user friendliness to the next level with a new smartphone app that simplify design, installation, service, and use. The solution includes four new products: new case controller platform, electric expansion valve, pressure transmitter, and temperature sensor – all designed for an optimum solution.

“For many food retailers, reducing costs is a number one priority”, says Ejnar Luckmann, Product Manager for case controllers at Danfoss. “At the same time, retailers need to ensure consistent refrigeration performance at all times so food safety is never compromised. Reaching both of these targets requires a refrigeration system that can automatically adapt to changing conditions.

Now Danfoss offers a solution that makes it easier than ever to save on adaptive and reliable food retail refrigeration: the new generation of the proven ADAP-KOOL® Case Controls Solution. It delivers energy savings of 6-10% compared to the next best alternative, and it includes features that improve the user experience for OEMs, installers, and end users by simplifying design, installation, and service.

Four new products, one complete solution

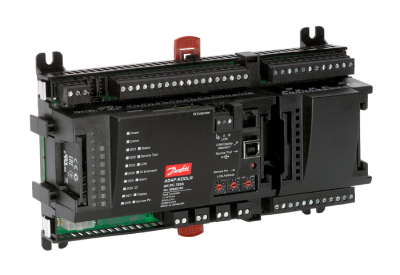

The AK-CC55 case controller relies on advanced Danfoss algorithms to control cases, cabinets, and cold rooms. User can, via a Bluetooth display, communicate with the controller using the new AK-CC55 Connect smartphone app.

- – Significant energy savings with adaptive superheat control algorithms and adaptive defrost

- – Simplified installation and service with smartphone app and large terminals

- – Suitable for any store size with Compact, Single Coil, and Multi Coil versions

The AKVP electronic expansion valve (EEV) series combines the existing AKV and AKVH series into a single solution, covering both HFCs and CO2. Thereby, it both reduces complexity as well as delivers several improvements.

- – Improved performance with increased capacity

- – Reliable compressor protection with fail-safe valve closure in case of power cuts

- – Optimized refrigerant distribution and quiet operation with soft pulse technology

The AKS 11 temperature sensor carries on the Danfoss tradition for reliability, robustness, accuracy, and fast response times, but with new features that makes life easier for the designer and installer.

- – Easier installation and troubleshooting with colored sensor cables

The DST P110 pressure transmitter delivers high accuracy and fast response times in a sensor solution designed to resist extreme vibration, temperature change, and electrical interference.

- – More efficient superheat control with improved accuracy in a lower temperature range

- – Rugged and reliable with corrosion-resistant, IP67 classified stainless-steel housing

Better user experience and significant savings

Together, the four new products create a complete ADAP-KOOL® Case Control solution that delivers significant benefits in all food retail applications.

- – Food retailers can reduce their energy bills while ensuring food safety. The smartphone app can drastically shorten service and maintenance procedures, saving time and money. “The AK-CC55 Connect app is so easy and intuitive to use that even non-specialists might use it,” remarks Ejnar Luckmann. “With the app, it is often not necessary to take the cabinet apart to check the refrigeration system. Users can get a fast and easy first-time fix and thereby reduce downtime, food loss and revenue losses”.

- – Installers and contractors can achieve faster and easier system installation and service. In addition to the smartphone app, the solution offers several practical benefits. “For example, the large terminals on the AK-CC55 make it easy to loop the pressure transmitter cable from one controller to the next one” explains Ejnar Luckmann. “Also, the new color-coded AKS 11 sensor cables make it easy to install and verify correct sensor positioning”.

- – OEMs can quickly design a refrigeration solution for any store irrespective of store size, refrigerant, and control requirements using the new solution. The new ADAP-KOOL® generation is fully backwards compatible with existing Danfoss refrigeration systems, making system redesign and extension easier and less costly.

‘ADAP-KOOL the way you work’

For more than three decades, the ADAP-KOOL® solution has been defined by the same basic values: robust, reliable, and adaptive display case and cold room refrigeration that ensures high food safety and significant energy savings. With the new generation of ADAP-KOOL®, it is easier than ever to realize the benefits of those values in food retail applications.“With the new generation, the system provides the same great value and now delivers a much better user experience, no matter if you’re an OEM, installer, service technician, or food retailer” concludes Ejnar Luckmann. “The new generation is more than a solution; it’s a way of working. That’s why we say, ‘ADAP-KOOL® the way you work’”