Weidmüller’s SNAP IN Connection Technology – Quick. Simple. Safe. Ready-to-Robot.

June 15, 2023

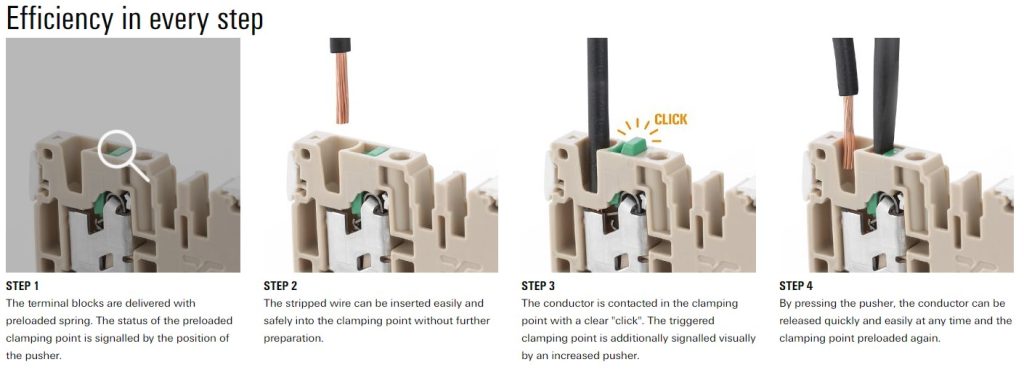

The future of connections is Weidmüller’s new, patented SNAP IN connection technology that is revolutionizing the wiring process of control cabinets. SNAP IN connection technology features simple and intuitive handling. The pre-loaded clamping point allows direct and tool-free wiring of solid and flexible conductors – even conductors without the ferrules. Simply insert the conductor into the connection point. You will hear an audible “click” and you will see a visible increase in the pusher, and you will know that a reliable connection is ready.

It is just as easy to remove the wiring as it is to insert it. Simply press the pusher, and the conductor can be quickly and easily released at any time, and the clamping point can be pre-loaded again. The pre-tensioned contact point designed for SNAP IN connection technology ensures reliable contacting of the conductor and guarantees that the wire connection is gas-tight, is protected against vibration, and is stable for the long term.

Automation in panel building increasingly demands new requirements for terminal blocks. Weidmüller’s SNAP IN connection technology is future-ready and ready-to-robot with an optimized design that supports robot-assisted assembly. The simple and safe handling of Weidmüller’s SNAP IN connection technology facilitates the use of automated wiring processes – and prevents incorrect wiring. The fastest connection technology on the market is ready for the future.

SNAP IN connection technology can be found in Weidmüller’s new Klippon® Connect terminal blocks, the world’s first terminal block with innovative SNAP IN technology, and in Weidmüller’s OMNIMATE® 4.0 PCB terminals and connectors, the modular connector that allows you to create your own configuration.

Try it for yourself. Ask for a free sample today.

More Information

Related Story

Weidmüller and New Energy in Canada

Weidmüller is well-known for its products that are engineered for the traditional energy markets. Today, across the globe, there is a push when it comes to new energy and renewable energy. Weidmüller Canada is well-positioned to serve this market with industry-specific products in solar, wind, and hydrogen. Canadian companies who want to break into the new energy space can turn to Weidmüller, not only for their products and solutions, but also for an industry partner who will support them on their journey of implementing new energy solutions into their operations.