The Perfect Cable Tie for Solar: Nylon 612

April 26, 2024

Nylon 612 Cable Ties are Perfect for Solar: Panduit Has a Million Reasons Why

The average 100 MW solar project uses more than one million cable ties to manage miles of PV wire at every stage of the DC distribution system. Typical plastic ties are not expected to last the entire 25+ year operating life of a solar power plant. When they fail, you end up paying for a new tie and the labor for installation, which adds up fast. However, certain nylon blends perform much better in this challenging application than others, so choosing the right tie helps maximize long-term reliability and return on investment .

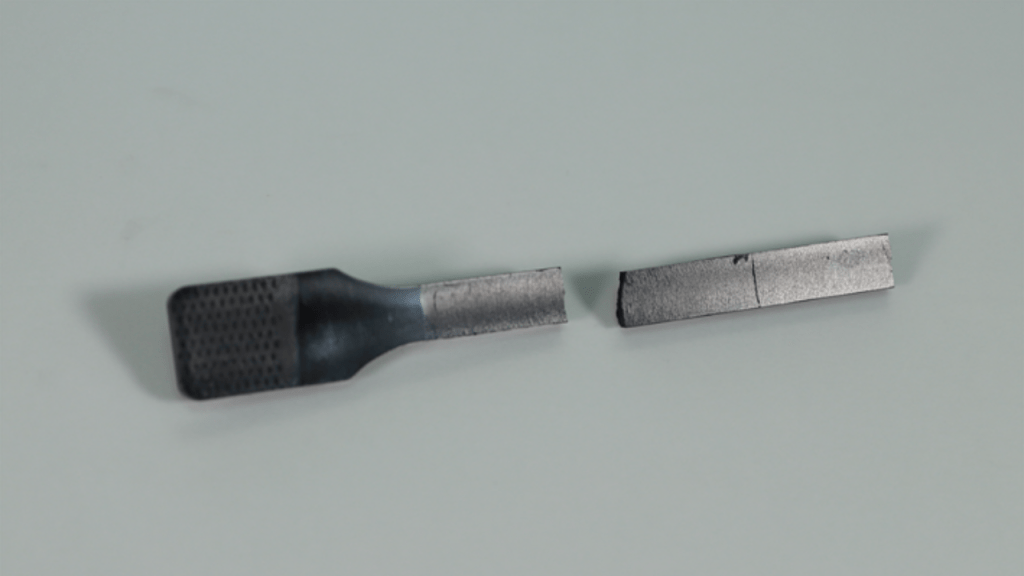

Ultraviolet (UV) radiation in sunlight is destructive to most plastics, including the nylon commonly used to make cable ties. Plastics exposed to UV radiation will either absorb it or produce free radicals – highly unstable molecules with one unpaired electron – that break down the bonds between molecules in the material. Visually, you might notice a chalk-like coating, cracks on the surface, or color fading on UV degraded nylon. UV degraded cable ties have a fraction of the original tensile strength and will fail in time.

To improve UV resistance, materials engineers introduce additives to block UV, absorb UV, or stabilize the nylon. For example, common outdoor rated Nylon 6.6 has more carbon atoms to block most UV radiation before it can interfere with the molecular bonds. While ties made of this material will eventually fail in the sun, the carbon black significantly prolongs the usable life compared to non-outdoor rated ties.

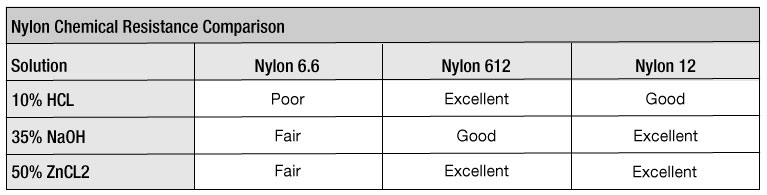

Beyond UV, other everyday environmental factors stress plastics in outdoor environments. Atmospheric moisture from rain and fog has varying pH levels, and costal installations are exposed to higher salt levels because of the marine environment. In cases where moisture interacts with coated metals, weak concentrations of Zinc Chloride can be found in the runoff. Though nylon is naturally considered to have good chemical resistance, the harsh conditions and long operating life of solar farms can push the limits, leading to failures.

Nylon 12 is a formulation with 12 carbon atoms in each molecule that absorbs very little moisture and resists chemical degradation especially well. Traditionally, it has been the premium go-to cable tie material for projects where chemical interactions from materials or environment are expected. Because it costs considerably more than standard 6.6 it is used in a relatively low percentage of solar builds.

Enter Nylon 612, the perfect material for a solar cable tie. This formulation has the characteristics of both nylon 6 and nylon 12. It can withstand UV exposure up to 10 times longer than standard black cable ties and has excellent environmental durability, resisting the long-term effects of varying temperatures, changes in humidity, and chemical exposure.

Because of these properties, Panduit nylon 612 cable ties have an expected outdoor lifespan of over 20 years and are backed by the 20-year Build Solar Better Warranty. This gives installers the benefit of “fit and forget” reliability and reduces long-term maintenance costs to improve return on investment. Our Nylon 612 cable ties are built to the high-performance Panduit Premium specification to offer industry-leading ease of installation and the highest quality standards. Best of all, they are significantly less expensive than comparable nylon 12 ties and only a slight price premium to more common 6.6.

Of course, there are many different ways to approach cable management in solar projects and some engineers prefer to avoid plastics all together. Stainless steel solutions offer even greater durability and typically can be relied on to last the life of the project. Our contractor-grade stainless Stronghold ties strike a nice balance between speed, simplicity, and durability. And depending on the project, Solar Wire Hangers may offer attractive process flexibility.

In addition to cable management, Panduit offers a broad portfolio of solar Balance of System (BOS) solutions , including power and grounding, labeling, and network infrastructure. If you’d like to discuss wire management, or any aspect of Solar BOS our team is here to help. Visit our Solar Solutions page to learn more.

Related Story

Panduit Receives Canada Standards Association Certification for its Cable Cleats

Panduit, a global leader in innovative electrical and network infrastructure solutions, announces it has successfully complied and received certification for its cable cleats in accordance with the recently published technical standard by the Canadian Standards Association (CSA). CSA C22.2 No.61914:23 Cable Cleats for Electrical Installations, was published in early October 2023. This achievement underscores the company’s ongoing dedication to providing cutting-edge, safe, and reliable solutions to meet the ever-evolving demands of the industry.