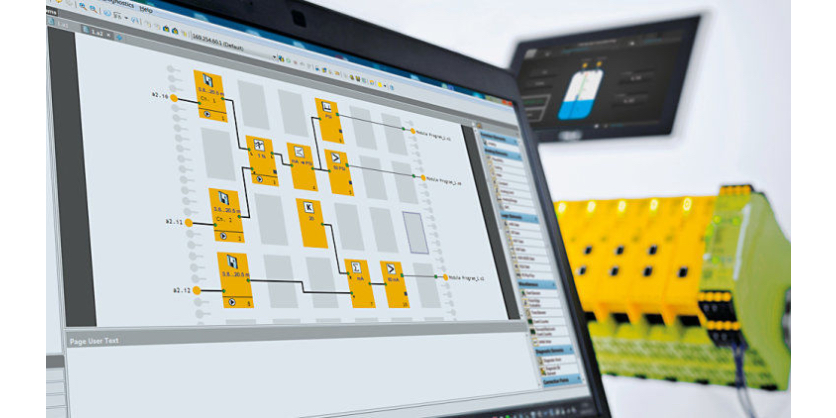

Software PNOZmulti Configurator – What’s New in Version 11.3

The original safety circuit configuration tool for the small controllers PNOZmulti

December 20, 2023

Laser scanner function blocks for PSENscan, motion monitoring for AGVS

From software version 11.3.0, new blocks provide for the most secure und flexible monitoring of the:

Laser scanner PSENscan:

The zone selection function block enables productive solutions for stationary and mobile danger zone safeguarding in conjunction with the safety laser scanner PSENscan, used to monitor 2D zones. In this way, for example, it is possible to monitor open robot cells safely, or also guarantee efficient processes in a logistics or production environment.

Automated guided vehicle systems (AGVS):

Motion monitoring software blocks for safe synchronisation monitoring, for example, plus three others for safe position monitoring (Safe Position Comparison, Safe Position Range and Safe Position Monitoring), are available for monitoring automated guided vehicle systems (AGVS). They are used in conjunction with the safe motion monitoring modules PNOZmulti 2.

- With safe synchronisation monitoring, two axes are compared – a comparison is possible based on higher, lower or same speed. Tolerance windows can be defined in the software tool, enabling an even more flexible application. PNOZ m EF 2MM is the module of choice in this regard. Safe detection of anomalies in the synchronisation of two axes protects human and machine. Also, synchronous operation can be monitored on synchronous axes. Safe path detection is enabled by monitoring and comparing the two drive axes on an AGVS.

- When safe position monitoring is used, the position and position range of an axis can be monitored. The modules PNOZ m EF 1MM/2MM/1MM 2DO can be used for this purpose. The steering axis and current position of an axis can be monitored safely once a reference marker to detect the zero point has been set.

Hardware – Perfectly tailored to the application:

- The input module PNOZ m ES 16DI has 16 digital inputs and monitors standard applications.

- The communication module PNOZ m EF EtherCAT FSoE enables safe data transfer with Safety over EtherCAT in conjunction with the base unit PNOZ m B1. PNOZmulti 2 can be used as FSoE Master, FSoE Slave or EtherCAT Slave.

- Decentralised input and output modules PDP67 F 10DI4DO (VA) forward signals from the connected sensors to the safe small controller PNOZmulti 2. New features are the four safe semiconductor outputs on the PDP67, which enable safe sensor technology such as the modular safety gate system PSENmlock to be connected directly to the PNOZmulti 2 via cable. Up to four of the modules with protection type IP67 can be connected to the PNOZmulti 2 via the link module PNOZ m EF PDP-Link. Up to four safe sensors per PDP67 module – a total of up to 64 sensors – can be monitored flexibly in the field in this way. A version with stainless steel screw connections is available, for use in the food industry for example. M12 plug-in connectors link sensors and actuators quickly and easily to the PDP67 module. Complicated wiring is avoided. That reduces costs when expanding and commissioning modular production plants.

Your application advantages:

- Maximum flexibility due to the module program configuration

- Safe solutions for stationary and mobile danger zone safeguarding with the laser scanner PSENscan

- Parameters for motion monitoring safety functions are easily set via software, for the safe monitoring of automated guided vehicle systems (AGVS)

- Software tool can be used free of licensing costs

Download now! No licence costs – Version 11.3 PNOZmulti Configurator

More Information

Software tool PNOZmulti Configurator

Related Story

Pilz Is Expanding Its Worldwide Online Training Offer: Machinery Safety Knowledge – Live, From Anywhere

The automation expert Pilz is expanding its worldwide digital training offer for machinery safety. With the new “International Training Calendar”, standardized training courses from Pilz can now be attended live online. So, the training offer is also available in regions where Pilz does not have a subsidiary. As a result, Pilz makes it easier for customers to access knowledge sharing and gives them greater flexibility for further training in key areas of machinery safety.