Siemens Xcelerator for Digital Drivetrain — Comprehensive Digitalization Offering Along the Drivetrain Value Chain for Greater Efficiency and Sustainability

May 22, 2024

- DriveSim Engineer for efficient selection, validation, virtual commissioning and optimization of drivetrain systems

- Intelligent condition monitoring for a healthy drivetrain with Drivetrain Analyzer Cloud and Drivetrain Analyzer X tools

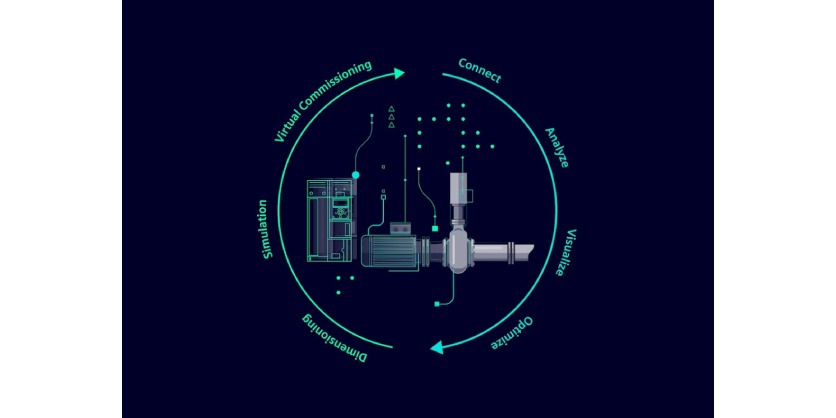

At this year’s AUTOMATE, Siemens presented Siemens Xcelerator for Digital Drivetrain, its comprehensive and integrated digitalization offering along the drivetrain value chain comprised of two areas: Drivetrain Design (dimensioning and simulation) and Drivetrain Health (connectivity and optimization).

Drivetrain Design includes engineering and simulation tools for the efficient dimensioning, validation, testing, virtual commissioning, and optimization of drivetrains in the design phase

of a machine or system.

Drivetrain Health offers hardware- and software-based sensor and connectivity solutions for data acquisition as well as coordinated analysis software tools. These tools provide insights into the behavior of the drivetrain and enable powerful condition monitoring. Siemens is thus demonstrating how customers can combine the real and digital worlds of drive technology to achieve efficiency and sustainability along the entire drivetrain value chain.

DriveSim Engineer for efficient selection, validation, virtual commissioning, and optimization of drive systems

In the area of simulation and virtual commissioning, Siemens is launching DriveSim Engineer, the successor to DriveSim Advanced. DriveSim Engineer makes it possible to create a digital twin of the drive in a virtual environment with all the parameters and configurations that correspond to the real drive. In addition to the new SINAMICS S210 series, the new SINAMICS G220 frequency converters are now also available in the tool. Digital twin technology and the intuitive user interface allow users to simulate, commission, and optimize the behavior of drive systems in a virtual environment before installing them in the real world. This significantly increases efficiency and productivity in the engineering of drive systems and machines

Thanks to its integration in TIA Portal (Startdrive), DriveSim Engineer is a seamless part of (virtual) commissioning and makes training in additional tools superfluous. Users benefit from shorter commissioning times, more accuracy in detecting and resolving potential problems with drive systems, and real-time insights and analyses for improving the overall performance of drive systems.

Intelligent condition monitoring for a healthy drivetrain

Another new product is the Connection Module IOT (CM IOT), which can be installed and put into operation in just a few minutes. Highlights include the improved, additional sensor technology, the new alternative energy concept via an external 24V connection, and a housing and component update. The module measures raw data and automatically transfers it to the cloud.

Siemens presented two intelligent solution packages for high-performance condition monitoring: a cloud-based solution and a PC-based solution. The two complement each other and can be used according to requirements. With Drivetrain Analyzer Cloud, Siemens combines the two applications Analyze MyDrives and Sidrive IQ Fleet into one innovative app. In addition to a new user interface, Drivetrain Analyzer Cloud offers users the option of connecting various drive components such as variable frequency drives, motors or other rotating machines to a drivetrain and monitoring the drivetrain’s status.

Drivetrain Analyzer Cloud provides immediate information about anomalies and specific error patterns such as bearing damage, imbalances, or misalignments, thereby helping to prevent unplanned downtime. The cost-efficient solution combines condition monitoring with decarbonization by supplying the user with important additional data and energy costs. Another new feature is pump analytics, which Drivetrain Analyzer Cloud can use to calculate and analyze system efficiency and specific pump parameters.

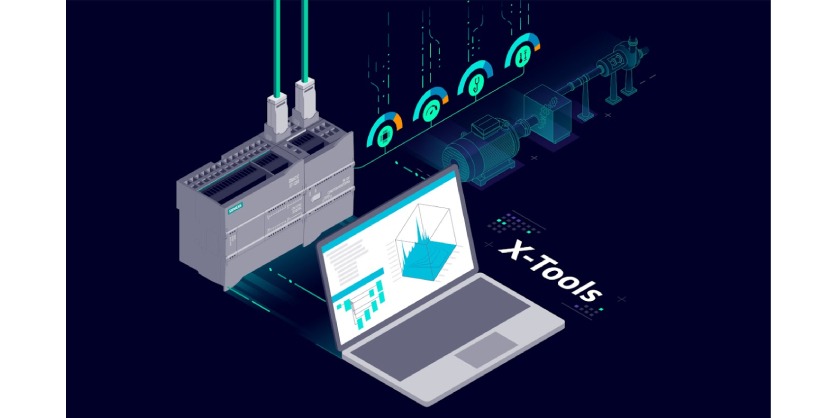

In addition to the cloud solution, Siemens also presented another new product, a PC-based condition monitoring solution consisting of three components: the new VIB (Vibration) and FPP (Fast Process Parameters) (CM FPP) connection modules, the Drivetrain Analyzer X-Tools software, and the corresponding sensors and sensor cables. The CM VIB and CM FPP connectivity modules record vibration and analog signals at a sampling rate of 96 kHz. All sensor information can be recorded and transmitted synchronously.

Now users can also analyze high-speed, intermittent machines such as automotive presses, cranes, or machine tools with two synchronous axes. Drivetrain Analyzer X-Tools is an expert tool for highly dynamic data acquisition up to 192 kHz as well as for manual data analysis. Because X-Tools can connect to almost any data source, users can ideally use X-Tools as

an analytics toolbox to link their own analytics with elements of a preconfigured library.

For example, the software can be used to monitor bearing temperature, housing vibrations, and oil lubrication, meaning pressure and flow, in heavy machinery equipped with plain bearings. In this way, Drivetrain Analyzer X-Tools and the new connectivity modules contribute to higher machine availability, better performance, and a longer system service life.

With Siemens Xcelerator for Digital Drivetrain, Siemens introduced a comprehensive range of IoT-capable hardware and software for the entire drivetrain from the Siemens Xcelerator portfolio for the first time in the US at AUTOMATE 2024.

More Information

To learn more about Siemens Digital Drive Train, please visit: usa.siemens.com/ddt-pr

Related Story

Siemens Xcelerator: Scaling Roll-Out of Generative AI with Siemens Industrial Copilot

At Hannover Messe 2024, Siemens presents the first generative artificial intelligence (AI) product for engineering in an industrial environment. The Siemens Industrial Copilot, the generative AI-powered assistant, is now seamlessly connected to the Totally Integrated Automation (TIA) Portal. This will enable engineering teams to find the right help topic and to generate a basic visualization and code faster for programmable logic controllers (PLC).