Siemens’ NX Delivers Greater Cross-Discipline Collaboration and Knowledge Capture

July 6, 2022

The latest release of Siemens’ NX brings new collaborative tools for mechanical/electronic teams, greater knowledge capture and reuse, and more holistic optimization along with a number of extensions to existing capabilities.

Siemens Digital Industries Software recently announced that the latest release of Siemens’ NX™ software, an industry leading product engineering solution, brings greater electronic co-design, collaboration, and intelligence capture and reuse capability. These empower engineering executives across every industry to find productivity improvements and greater efficiencies in their engineering departments.

“Innovators and pioneers, from clean-sheet start-ups to household name brands, are adopting NX and choosing us as a trusted partner, as we explore the future of design, engineering and manufacturing together,” said Bob Haubrock, Senior Vice President, Product Engineering Software, Siemens. “This latest release brings enhancements to our users across the board, enabling them to work more intelligently between multidisciplinary teams, capture and reuse more knowledge and achieve that optimum design more efficiently than ever before. Alongside brand-new functionality, our significant investments to core technologies, such as sketch and convergent modeling, will further improve the toolsets that our community of users relies on every day.”

Part of the Siemens Xcelerator portfolio of software and services, NX delivers productivity and user-experience enhancements across a broad range of capabilities.

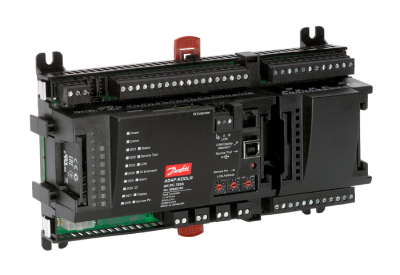

Leveraging our leadership and expertise in the electronics/electrical engineering space with Siemens EDA (formerly Mentor Graphics), NX extends its electronic design collaboration capabilities further with a robust workflow for rigid and rigid-flex PCB designs. These are especially important given increased product complexity and packaging constraints.

Users will notice a new codeless approach to Feature Templates that enables the reuse of the knowledge embedded into NX data during design. This elevates user-defined features to the next level, extending data reuse from pure parametric geometry features to include PMI, requirements checks and more. The key benefit is a jump start of efficient knowledge reuse and greater collaboration amongst design and engineering teams.

NX is renowned for its leadership in complex shape development and whatever the industry sector customers operate within, aesthetic quality is now just as important as functionality, efficiency and performance. The latest release of NX brings new tools to help develop the forms designers need and their customers demand, whether that’s updates to curve creation and editing with parametric features or to NX Algorithmic Modeling which better support convergent modeling workflows enabling more efficient ways to complex patterns and shapes.

NX Topology Optimizer now fully replaces and surpasses our previous solution capabilities. Part optimization within the context of an assembly now considers design and manufacturing constraints and makes simultaneous optimization of multiple design spaces with independent materials possible.

The recently introduced NX Design Space Explorer for multi-objective optimization also now offers multi-run support to fine tune ranges and refine searches and Simcenter™ HEEDS™ software run options are now fully integrated and cover baseline, random seed, and normalization factors. This will enable customers to benefit from both cost and time savings through automation of complex optimization tasks helping them to achieve faster time to market during the design engineering phase of product development.

“Today’s mechanical products are complex, and engineers need to integrate mechanical, electrical and electronics. Bringing the data from each of these disciplines can create design friction, which needs to be resolved quickly,” said Arvind Krishnan, industry analyst, Lifecycle Insights. “A good example is the placement of a cooling fan in an electronic housing. The engineers benefit by working in a collaborative environment. So, when there is a change in the electronic board design, the mechanical engineer responsible for the fan and housing design can respond, and vice versa. NX provides best-in-class electromechanical design tools, smoothly weaving together the different needs of the mechanical, electrical, and electronic disciplines into exactly that tightly integrated collaborative environment.”

For additional information about the latest release of Siemens’ NX, read the NX overview blog post or watch the Youtube Premiere event that occured on June 21, 2022 at 11:00 am Eastern Standard Time – it remains available to view at any time and can be embedded where required.