Siemens and Nexii Announce VersiCharge XL Available for Commercial Market Deployment

August 18, 2023

Meant for high-volume charging areas like airports or hospitals, VersiCharge XL can be quickly installed, is easily scalable for fleets, and reduces environmental impact by using low-carbon components and modular installation.

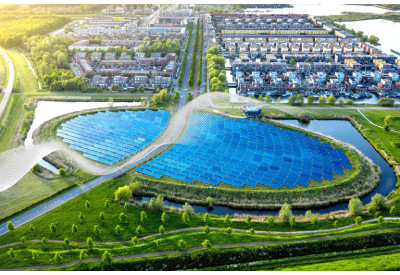

Siemens has announced commercial availability of the VersiCharge XL, a sustainable electric vehicle (EV) charging structure designed for electrifying fleets at high demand charging sites. Designed and produced in partnership with Nexii Building Solutions (Nexii), a green building solutions company, VersiCharge XL is the first EV charging structure that is comprised of sustainable, low carbon building materials with a modular and scalable design that allows for quick and efficient installation and maintenance.

This solution contains all the necessary electrical infrastructure components to provide power to EV chargers in an above ground, enclosed, and durable design. The charging station power supply can easily be deployed in existing or new parking lots and building structures, requiring minimal disruption to existing environments by removing costly, time-consuming, and substantial civil works and reduces on-site construction waste and environmental impact. Once installed, the VersiCharge XL can provide the power to charge a large number of EVs including buses, trucks and other medium and heavy-duty vehicles in environments ranging from last mile logistics hubs to malls, airports, or stadium parking lots.

An alternative infrastructure in the market today would often require trenching and excavation work, which can cause significant disruption to roads and businesses. This can lead to increased costs and longer installation times. In addition, trenching and excavation work can also be a source of environmental concerns.

“This unique solution helps address the sense of urgency we as an industry face to meet a growing market right now with the ability to easily scale up as needed in the future,” said John DeBoer, head of Siemens eMobility North America. “We’re excited to bring the VersiCharge XL to market that can eliminate up to 90 percent of the underground cable requirements to limit environmental disruption – all while advancing an open and accessible nationwide charging network.”

John DeBoer, head of Siemens eMobility North America

VersiCharge XL is created using Nexii’s building material Nexiite, which has comparable properties to concrete with significantly less embodied carbon. The busway power distribution equipment for the VersiCharge XL is manufactured at Siemens manufacturing facility in Spartanburg, South Carolina.

“This collaboration combines Nexii’s breakthrough building technology with Siemens’ expertise in electrical infrastructure to create a product that not only provides the power for electric vehicle chargers more efficiently but also seamlessly integrates with our sustainable building solutions,” said Gregor Robertson, EVP of Strategy and Partnership at Nexii. “Our EV charging infrastructure results in 45% less embodied carbon pollution when disassembled for reuse. This will revolutionize the way we supply power to charge our electric vehicles, making sustainable transportation more accessible and convenient for all.”

Gregor Robertson, EVP of Strategy and Partnership at Nexii.

First introduced as a prototype last year, the concept was installed in just three days at Siemens eMobility R&D hub and North American headquarters for Siemens Electrical Products in Peachtree Corners, Georgia. This location is one of a growing number of U.S. facilities where Siemens engineers and researchers are working towards the future of electrified transportation.

Siemens eMobility includes manufactures AC and DC chargers deployed in all 50 states that range from in-home chargers to fleet depots to charging infrastructure systems that power electrified bus lines in some of the largest cities in the country. The Siemens PlugtoGrid™ eMobility product portfolio encompasses charging infrastructure hardware, electrical equipment, software, and services in the EV market across North America.

Across the United States, Siemens is investing in existing and new sites that develop electrical equipment for critical infrastructure systems including EV charging, data centers, and industrial installations, advancing Siemens’ commitment to support the next generation of American infrastructure.

More Information

Related Story

Nexii Building Solutions – Reinventing the Way the World Builds

Nexii Building Solutions is a green construction company that is reinventing the way the world builds. It designs and manufactures high-performance green buildings and building products that are sustainable, cost-effective, and climate resilient. In this article, we sit down with Zosia Brown, VP of Sustainability, Nexii Building Solutions, to discuss the company’s innovative technologies and how it is breaking new ground and going beyond expectations.