Sensors for Water Tanks by Gems Sensors & Controls

June 22, 2022

Commonly, point-level and continuous sensor types are known as water level sensors. Point-level sensors (often called switches) detect water’s presence (or absence) at a fixed location in the tank. They usually indicate high or low water levels for alarms and pump control, but there are numerous unique applications for point-level sensors.

Continuous level sensors (sometimes known as transmitters) provide an uninterrupted scaled linear value to transmit water level or tank volume to a control device or operator display. They provide more accurate real-time monitoring or control of water levels where required.

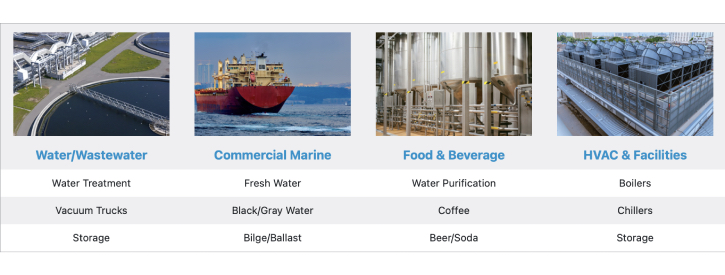

Gems Sensors offers a variety of products to support many water tank applications. Point-level and continuous level, pressure, temperature, and flow sensors perform different functions when monitoring or controlling processes involving a water tank.

Here are just a few,

As in the examples above, different water qualities or conditions require solutions for accurate sensing. Are there contaminants? Is the water deionized or purified? Is this a mobile application where turbulence or sloshing can occur? What is the temperature range for the water? Many more factors provide guidance when choosing the correct sensor.

Water tanks often use multiple sensors to cover a range of functions. Examples of the kinds of sensors commonly used:

Single Point Level Sensors

Single point-level sensors (or level switches) provide pump control or high/low-level detection for alarms. There are a few technologies available to best match the application. Float type, electro-optic, ultrasonic, and capacitive sensors are common. The ULS-100 Universal Level Sensor is an ideal choice for use in water tanks.

Multi-Point Level Sensors

Multi-point level sensors are primarily float-type. They can be very similar to the single point, but a longer stem with more than one level float provides several switch points. Also, they are typical for high/low detection and pump service.

Continuous Level Sensors

Continuous level sensors do not use fixed switch “points”, but rather measure the precise level (or volume) of the water in the tank at any location within a scaled linear range. The linear measurement is transmitted back to a display or control device via voltage, current, or resistance. Ultrasonic, float-type, guided wave radar, and non-contact radar are continuous level sensor types. Ultrasonic and non-contact radar are suitable for many instances where touching the liquid media is to be avoided, such as the RLI-80 Non-Contact Radar Level Sensor.

Boiler Control Conductive Level Sensors

Warrick conductivity controls consist of probes or electrodes and a control relay board. Continuity is determined when electrons flow between probes using the water as the conductor. It sends the electrical current to the control relay to switch states in applications such as single-level service and pump control. Additional applications include low water cut-off safety devices in boilers.

Visual Level Indicators

Gems SureSite® visual level indicators are float-type devices. The magnetic floats travel through a tube, where external indicator flags flip to show a contrasting color from outside the water tank that signifies the current level.

Pressure Sensors

When traditional continuous water tank level measurement is impossible due to extreme motion, sloshing, and turbulence, the Gems 5000 series solid-state hydrostatic pressure sensor is an ideal choice. As the volume in a water tank increases or decreases, it results in a change in pressure. Volume or level is measured and transmitted with the 5000 series based on this principle.

Flow Sensors

Gems has an entire portfolio of flow switches and sensors that work in conjunction with monitoring the levels in water tanks. In many applications, inlet and outlet pipes feed and drain water tanks. Therefore, proper, unrestricted flow is necessary to maintain a safe and productive operation. Visual indication, flow/no-flow alarms, and continuous flow rate measuring are examples of the many valuable functions of Gems flow products covering all qualities of water, including potable.

Temperature Sensors

The temperature of the media in a water tank can be an essential parameter to monitor in many applications. Gems offers temperature transmitters and switches. Some are even integral to the level sensor, such as in the TH-800 Level Switch.

PMA and West brand control products provide the display and control of all water tank functions. The PMA KS-98-2 is a sophisticated process control system engineered for decentralized multi-sensor support and automation.