Schunk: Powerful 5-axis power vise with adjustable center

August 29, 2019

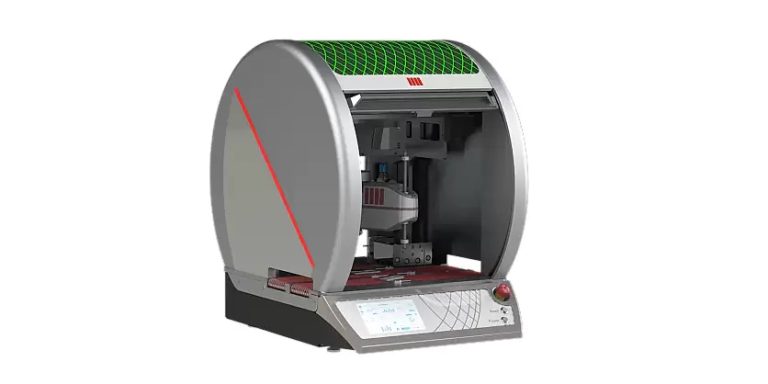

In response to high demand, SCHUNK has increased its product line of power-amplified 5-axis vises which are now equipped with an adjustable center: The maintenance-free SCHUNK KONTEC KSX-C is now available in four base body lengths (330 mm, 430 mm, 500 mm, and 630 mm) and two heights (174 mm, and 125 mm). The high-quality 5-axis vises have two jaws, which can be precisely moved by a laser-etched ruler. The clamping forces can be adjusted without tools between 4 kN and 40 kN, and are measured directly on the workpiece. The vise also provides plenty of power for a safe hold even in cases with mini-mal clamping surfaces. Workpieces are clamped within seconds with the help of 160° quick clamping in a vibration resistant manner and at a high repeat accuracy. Due to clamping by tension, the bending load at the base body is minimized. Moreover, the jaw guidance sys-tem and the arrangement of the clamping mechanism provide for a very rigid and dimen-sionally stable set-up, and therefore creates the ideal conditions for precise machining of the second side.

Fully encapsulated

The drive and the adjustment mechanism of the 5-axis vise are fully encapsulated, and therefore protected against the ingress of chips, dirt, and coolant. The easy-to-clean design of the vise avoids the accumulation of chips. Therefore, the KONTEC KSX-C can be seamless-ly integrated into the modular system for highly efficient workpiece clamping from SCHUNK. The clamping pins of the SCHUNK VERO-S quick-change pallet system can be used for direct mounting of the base body without requiring an adapter plate. Combined with the quick-change pallet system, the vise can be exchanged on the machine table within seconds and at maximum repeat accuracy. It can be equipped with standard, aluminum or special 5-axis top jaws, pendulum plates, or with many other standard jaws from the world’s largest range of standard chuck jaws from SCHUNK.