Rockwell Automation Provides Protection and Visibility with ASEM 6300 Industrial Computers and Monitors

February 15, 2024

ASEM 6300P Panel PCs are based on the seventh generation Core i3, i5 and i7 Intel Kaby Lake H and Intel Celeron Skylake processors to handle complex industrial applications

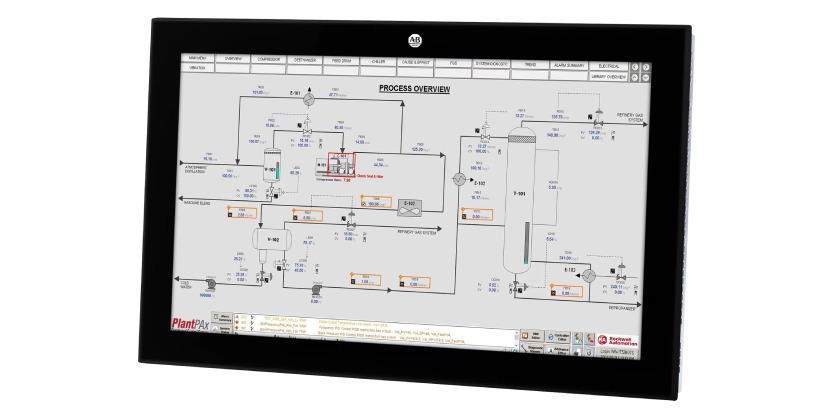

ASEM 6300 Industrial PCs are available in box and panel form and allow for greater customization. Innovation with FactoryTalk Optix software and seamless deployment to HMI solutions is available withthe ASEM 6300 device that best fits customer needs.

ASEM 6300 Industrial PCs are one of the solutions in the new FactoryTalk Optix portfolio. The FactoryTalk Optix portfolio allows users to choose their own technology mix, where for the first time, Rockwell Automation customers can use visualization software to design HMI applications that can natively work with both Rockwell Automation and third-party controllers and display a choice of hardware from either Rockwell Automation or a third-party. Users can connect to a variety of third-party software, devices or systems using software designed for interoperability and full OPC UA support. Users also only pay for the features they need with runtime licensing that is based on the capabilities in their application.

More Information

Click here to learn more about Rockwell Automation’s FactoryTalk Optix portfolio.

Related Product

Rockwell Automation Streamlines Machine Design, Development and Deployment with Micro800 Controllers and Automation Software Enhancements

Rockwell Automation streamlines machine design, development and Deployment with Micro800 Controllers and Automation Software enhancements.

Manufacturers can commission standalone machines more efficiently with Allen‑Bradley Micro820 controller firmware revision 14, and Micro850 2080-L50E and Micro870 2080-L70E controller firmware revision 22. The latest Connected Components Workbench software version 22 is the required minimum to support the expanded controller capabilities and improvements.