Rittal Automation Systems – Revolutionizing Enclosure Manufacturing

January 29, 2024

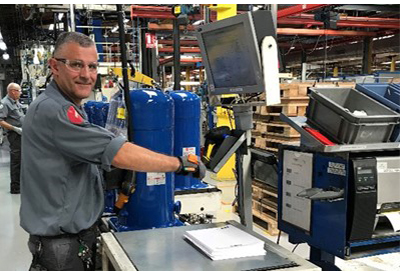

Elevate your enclosure production process with the cutting-edge solutions offered by Rittal Automation Systems. Representing a comprehensive suite of products and services, Rittal Automation Systems spans the spectrum from manual tools to state-of-the-art, fully automated machine technology tailored for enclosure manufacturing.

Experience accelerated, precise, and ergonomic machining and assembly of enclosures and components, addressing a myriad of tasks such as drilling, milling, laser cutting, bending, punching, population, and wiring. Rittal Automation Systems is your one-stop solution for unparalleled efficiency and performance.

Key Advantages of Rittal Automation Systems:

- Boosted Productivity and Efficiency: Slash machining and assembly time by up to 80% compared to conventional methods. Rittal’s Automation Systems offers high-performance, user-friendly machines and software, enhancing overall operational efficiency.

- Precision and Quality Excellence: Ensure consistent, error-free results with advanced technology and precision tools. Rittal’s Automation Systems handles a diverse range of machinable materials, including spray-finished sheet steel, stainless steel, aluminum, copper, and plastic.

- Safety and Ergonomics: Prioritize the well-being of your workforce with ergonomic, safe machine and tool designs. Integrated features such as dust extraction and noise reduction systems guarantee a clean and serene working environment, minimizing the risk of injuries and fatigue.

More Information

Related Product

Rittal Outdoor Protection for Trouble Free Operation Under the Harshest Conditions

The intelligent modular system comprising enclosure and climate control components offers you a multitude of choices for configuration of an individual outdoor solution. Benefit from the uniform design with built-in compatibility, look forward to delivery within 24/48 h and enjoy the convenience of a single supplier for all your product needs – for every field of application and for every climate zone.