New Range of Pad Mounting Motors from Lafert Group

January 10, 2024

The new range combines the proven robustness of Lafert’s asynchronous motors with new permanent-magnet technologies to reduce power consumption in a compact design

Born from the desire to meet the application needs of axial fans, the new pad mounting range combines the consolidated robustness of Lafert’s asynchronous motors with new permanent magnet technologies that reduce power consumption in a compact design with no protruding elements.

By minimizing the impact on airflow and the TEAO design – without ventilation, Lafert makes the system more efficient and high performance

Lafert’s pad mounting range

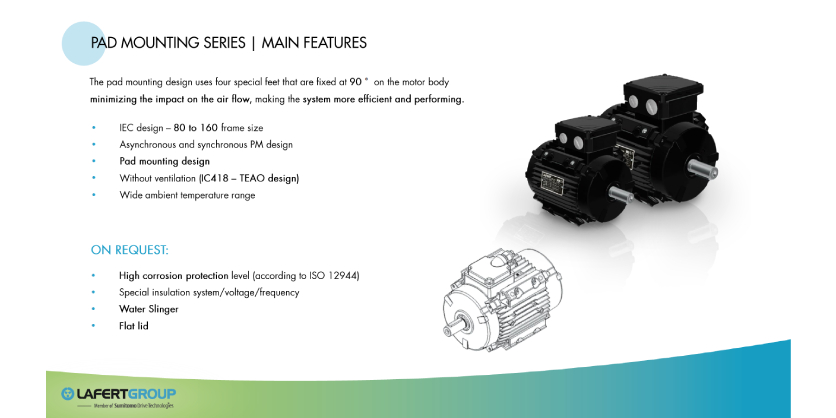

Perfect where mounting is needed for motors with small dimensions and no protruding elements, Lafert’s range allows minimizing the impact on airflow. The mounting design uses four special feet fixed at 90° to the motor body, eliminating possible air obstruction and ensuring reduced energy consumption.

They have developed a range of pad mount feet on IEC mechanics, from size 80 to 160, to meet all application needs. They can offer in this special mounting configuration both our asynchronous motors in efficiency class IE1, IE2 and IE3 and permanent magnet synchronous motors with efficiency IE4 and IE5.

Thanks to the on-demand anti-corrosion treatment to achieve the high level of protection in accordance with ISO 12944, Lafert’s motors are also perfectly suitable for aggressive environments.

The advantages: maximum efficiency and adaptability

Optimal operation over a wide temperature range and the robustness that distinguishes Lafert’s motors make theirs a special solution. Designed for both commercial and industrial environments and available with multiple customizations, the pad mounting range can be increasingly integrated with the final application.

Thanks to the different sizes/powers and technologies they offer, their motor adapts to the shape of the application without the need for further modification. In fact, it allows customers to upgrade to a higher efficiency solution without having to redesign their fan, simply by replacing the asynchronous motor with a higher energy efficiency permanent magnet solution.

In addition, thanks to the flat lid, their new ultra-compact terminal box design, the overall footprint of the motor is further reduced as well as airflow obstruction.

The water slinger option, a gasket with special conformation, manages to block any water splashes by repelling them outward, thus eliminating any possible infiltration.

More Information

Related Story

Lafert North America Ultra Premium Efficient IE5 High-Performance Motors, Italian-Made for Global Applications

The Lafert Group was founded in 1962, in San Donà di Piave, just outside of Venice. This area, called Veneto, is known as a region of hands and brains. It is here that the company began producing asynchronous electric motors, committed to the finest quality on the Italian market. Today, the San Donà facility is the headquarters of the Lafert Group, where their recent expansion was celebrated the same year as a special anniversary.

For sixty years, the company has developed cutting-edge technologies for energy efficiency and industrial automation, putting all their experience into building a more productive and sustainable future. Doug Backman, Director of Sales Lafert North America, discusses their motors and the company’s new plant that features fully automated production lines to produce them.