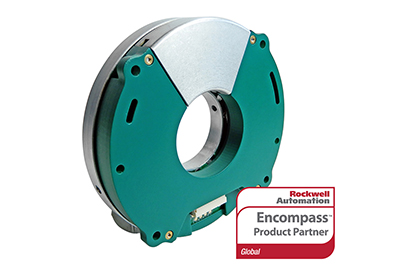

POSITAL-FRABA Multi-turn Hollow Shaft Kit Encoders Selected as Rockwell Encompass Complementary Products

November 12, 2019

POSTIAL-FRABA’s newly introduced Hollow Shaft Kit encoders have been selected as a complementary product in Rockwell Automation’s PartnerNetwork Encompass program.

These new products mark a significant innovation for industrial motion control. Until now, almost all through- or hollow-shaft encoders have been limited to a single-turn measurement range, largely because fully satisfactory multi-turn technology has been not been available. POSITAL has overcome this limitation with its new capacitive Hollow Shaft Kit encoders. They feature an integrated rotation counter that records each revolution the instrument experiences, even if these occur when no external power is available. Power for the counter circuitry is supplied by POSITAL’s well-proven, maintenance-free Wiegand energy harvesting system. There is no need for troublesome backup batteries or complex mechanical solutions.

The new Hollow Shaft Kit encoders are especially well suited to robots and cobots. Weighing in at just 110 g, with an outer diameter of 80 mm, they can be integrated directly into the joints of the robot arms. Their open-center form factor leaves room for designers to route mechanical components, cables or pneumatic/hydraulic lines through the center of the joint. Their slim design (only 17.8 mm deep) and large central opening (30 or 50 mm) make them ideal for space-critical applications, including servomotors and drives. Installation and commissioning are straightforward: a few simple steps and the measuring system is ready for use, without complicated calibration procedures.

While POSITAL earlier championed the switch from optical to magnetic measurement technologies in encoders, the new Hollow Shaft series represents a deliberate break with the past. Magnetic systems typically require that key components be placed on the centerline of the device, making it difficult to adapt to hollow center configurations. The capacitive measurement technique enables a ring-shaped configuration, while also offering reliability and precision (18-bit electronic resolution and an accuracy of ± 0.02 degrees) at a moderate cost.

Capacitive encoders have two key components, a rotor and a stator, which function as plates in a capacitive system. Capacitive coupling between the plates changes as the rotor turns relative to the stator, varying the modulation of electrical signals transmitted through the system. A sophisticated signal processing system analyzes changes in signal strength and phase angle to precisely determine the angular position of the rotor relative to the stator. Capacitive effects are integrated around the full circumference of the ring-shaped components, so that measurements are largely insensitive to dust, moisture of minor misalignments.

At the heart of the self-powered multi-turn system is POSITAL’s Wiegand energy harvesting technology. To accommodate the open-center layout, a new arrangement for the magnets (on the rotor) and Wiegand wire assembly had to be developed. Through experimentation and extensive magnetic field simulation, a reliable solution was developed that included four diametrical-oriented magnets placed evenly around the rotor. These four magnets provide a stable magnetic field that triggers polarity reversals in the Wiegand sensor installed in the stator. With each 360-degree rotation of the rotor, the Wiegand assembly generates a current pulse that energizes the counting electronics. This counter has a 43-bit memory for a measurement range of almost nine trillion revolutions. “These are values that put us right on trend for our target market,” says POSITAL-FRABA CEO Christian Leeser.

For more information, visit www.posital.com.