Pilz: PSENini Inductive Safety Switches

October 23, 2024

Safety switch for safe position detection

The inductive safety switches PSENini enable the safe detection of positions within a machine. They detect the approach of metallic objects without any contact, thereby supplying the necessary safe signals about positions and end limits. The inductive function principle minimises wear and increases the service life. You work safely, with high productivity!

Inductive safety switches – can be integrated flexibly

The PSENini detects positions such as end limits, for example, with safety and precision. This inductive proximity switch can also be used to generate the pulse for counting tasks or to detect rotational movements. In doing so the sensor does not need any specially coded actuators. It reacts to metals and can be integrated simply into the machine, saving space.

The different versions offer a high degree of flexibility for integration into your application. The cube-shaped proximity switch with plastic housing detects objects up to an operating distance of 15 mm. The three cylindrical versions with stainless steel housing enable operating distances of 2 to 10 mm and, with protection class IP68/IP69, are also suitable for more hygiene-critical application areas. The sensors also offer a temperature range of -25°C to +70°C.

Your benefits with the inductive safety sensor PSENini

- Reliable, with no blind range: no minimum distance required between sensor and object

- Versatile application options: four versions enable operating distances from 2 to 15 mm

- Can be used up to PL d, Cat. 2 (EN ISO 13849-1) / SIL 2 (IEC 62061); redundant use enables up to PL e, Cat. 3/SIL 3

- Can be used in hygiene-critical areas: stainless steel housing offers protection class IP68/IP69

- LED status indicator enables rapid diagnostics

- For versatile and robust use: insensitive to vibration, dust and humidity

- Easy to integrate: OSSD safety outputs enable direct connection to the safety controller

Inductive proximity switches PSENini are versatile in use

The inductive safety sensors are used in the widest range of applications, such as in packaging plants, in the food and beverage sector or in tool making, for example. Integration is really simple because the inductive safety switches have standardised OSSD safety outputs. This enables a direct connection to the appropriate safety controller, such as PNOZmulti, myPNOZ or PSS4000, for example.

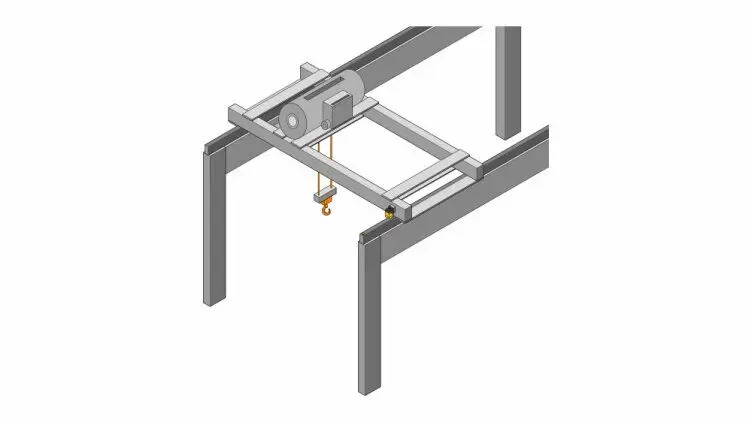

Safe position detection

When integrated in lifting crane applications, the inductive safety switch PSENini detects the respective end limits safely and reliably. PSENini identifies the current position of the lifting crane and, in conjunction with the appropriate safety controller – such as the configurable safe small controller PNOZmulti 2 for example – guarantees that the lifting crane moves safely. With an operating distance of 15 mm, the cube-shaped proximity switch PSEN in-D-A-N is ideal for this application.

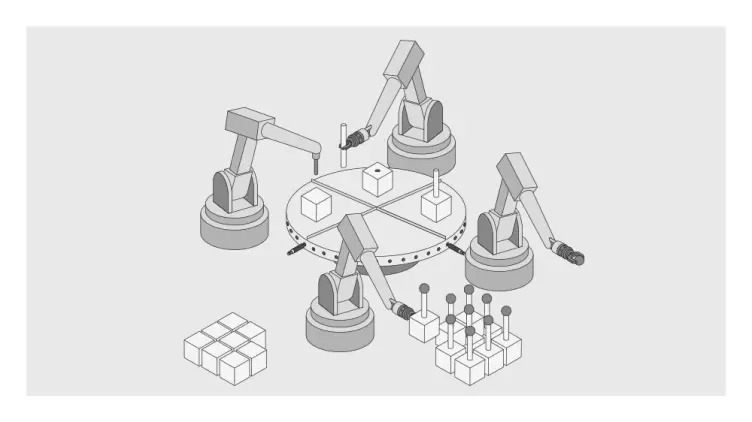

Safe speed monitoring

In addition to safe position detection, the inductive proximity switch PSENini also enables safe speed monitoring. As a result it is possible to determine the exact position of turntables, for example, to ensure that the required machining is carried out at the respective positions. Often there is little space available with these applications, so the cylindrical proximity switches PSENini, with their compact design and an operating distance of 2 to 10 mm, are ideally suitable in this case.

Pilz’s product range

PSENini

The inductive safety switch for safe, non-contact position detection

Accessories PSENini

Ideally compatible with the inductive safety switches PSENini: Assembly guide enable fast, simple installation

Connection Technology

You will find a wide selection of adapters and cables for the inductive safety switches PSENini here

Related Story

The New Industrial Security Consulting Service from Pilz

How do you protect machinery against cyber attacks, misuse by operators, or manipulation? In the future, Industrial Security will be an important component of the EC Declaration of Conformity. The new Industrial Security Consulting Service from Pilz is your solution. Their experts analyse your risk with regard to security vulnerabilities on the machine, ad create an appropriate concept for greater cyber security, plus increased employee protection and machine availability.