ROEQ’s New GuardCom System Delivers Faster Transfer of Goods Between Mobile Robots and Stationary Conveyors

October 27, 2020

Wi-Fi instability is a common workplace challenge. In material handling applications with devices communicating through complicated setups passing data around between mobile robots, 3rd party receiving stations and conveyors, an intermittent Wi-Fi network is prone to cause costly errors and downtime.

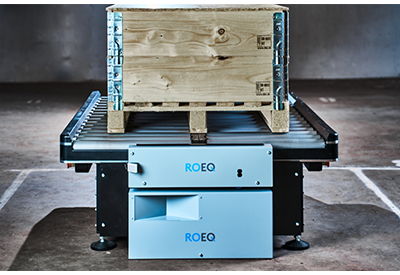

Having witnessed these connectivity issues first hand, ROEQ has recently launched GuardCom a seamless communication solution that enables Mobile Industrial Robots (MiR) equipped with ROEQ’s top rollers to communicate directly with the conveyor stations to initiate the transfer of goods between mobile robots and conveyors. The solution consists of two products; GuardCom installed on the stationary conveyor station, and GuardCom Connect installed on the autonomous mobile robot.

Multiple GuardCom Connects can work with the same GuardCom and vice versa. GuardCom is compatible with all stationary conveyor stations, replacing 3rd party wireless devices.

“With GuardCom we are delivering a safe, reliable and cost-efficient solution to eliminate wait times, errors, and accidents at cargo transfer stations,” says Michael Ejstrup Hansen, Managing Director at ROEQ. “GuardCom is truly the missing link that enables a completely seamless material handling cycle, resulting in shorter system integration time with less hassle and engineering costs.”

Once the mobile robot has arrived at the conveyor, GuardCom signals to the stationary conveyor station that the robot is in place and ready to receive or deliver the packages, same signal is simultaneously sent to the robot letting it know that the stationary conveyor is ready. Once the transfer task is completed, both units receive a signal that it is safe for the robot to leave.

The GuardCom is integrated into the stationary system via only a handful of cabled connections. The handshake process between the GuardCom and the mobile robot is completely wireless and based on proven and robust sensor technologies. To further prevent misplaced or dangling packages, GuardCom includes a physical guard installed on the conveyor station that goes up to prevent packages from rolling off and dropping to the floor when the autonomous mobile robot is not ready to receive. An alarm alerts the operator to come onsite to remedy the situation – or for the conveyor to roll backwards automatically.

Hartfiel Automation, a U.S. distributor of ROEQ products sees the GuardCom system as a shift in the way robots are deployed. “In the past, significant engineering development and 3rd party hardware was required to manage the logic of moving material from a stationary conveyor onto a mobile robot, which added substantial cost and time to deployments,” says Scott Albrecht, VP of Advanced Control Technologies at Hartfiel Automation. “With the ROEQ GuardCom system, these challenges are minimized or eliminated resulting in lower risk, lower cost, and faster deployment for these users.”

Transfer of heavier parcels now possible

GuardCom is not the only new product now released by the Danish company, that also introduces the new ROEQ TR500 Auto and TR1000 Auto top roller modules with automatic lifting mechanisms, enabling MiR’s largest robots, the MiR500 and MiR1000 (with 1100 and 2200lbs payload respectively) to pick up and deliver goods at varying heights in the factories without human intervention, which allows them to automatically adjust in a height range of 19.7 – 31.5in (stroke is 9.8in) from floor to rollers.

“Very often, businesses are not able to maximize automation opportunities in existing facility layouts as the mobile robots need to pick up at one height and deliver in another,” says ROEQ’s Managing Director. “Our new top rollers with the lifting mechanism now make this possible – even for the heaviest of goods.”

ROEQ’s expanded product portfolio now also includes the TR125 Manual 250 and TR125 Auto 250 top rollers compatible with MiR’s most recent robot release, the MiR250. At MiR, Frederik Spangtoft Poulsen, Product Manager at MiR, is looking forward to seeing the new ROEQ products deployed with MiR robots in the field. “We welcome ROEQ’s products into our MiRGo universe, a platform already featuring a significant share of solutions from ROEQ.”

For more information, visit https://roeq.dk/.