One Basic Device, Three Frequencies: Pepperl+Fuchs Presents a New, Modular RFID Handheld for Industrial Environments

November 9, 2021

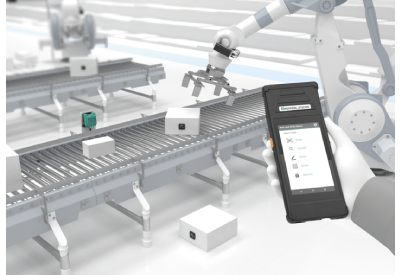

The introduction of the new, modular IC-HH5* RFID handhelds, means Pepperl+Fuchs is now offering a portable and highly flexible solution for writing and reading different frequency RFID transponders. The latest addition to the industrial automation product range boasts an especially user-friendly design and high-performance hardware. Using a sophisticated mechanism, RFID read/write heads for different frequencies (LF, HF, UHF) can be quickly and easily attached to the handheld’s base module without any tools.

The read/write heads are plug-and-play, allowing them to be interchanged during operation without needing any time-consuming configuration work. This ensures users can concentrate completely on the identification task at hand. To help with this, the basic device has a 4.8-inch capacitive, hardened color touch display, which can be read clearly at all times even in suboptimal ambient light conditions. IP54 protection emphasizes the device’s suitability for use outdoors and in other challenging environments.

The new RFID handheld is built around a high-performance Arm Cortex A53, quad-core processor with a 1.8 GHz clock frequency per core, and features an embedded Cortex M4, 400 MHz processor, which provides dedicated control of the RFID read/write heads. In addition to the powerful processors, the handheld has 2 GB of RAM and 16 GB of flash memory, providing quick access and fast processing times even when working with more complex software applications.

An integrated 2.4/5 GHz WLAN interface and Bluetooth support allow data to be exchanged with back-end systems and other handheld devices. In terms of software, Pepperl+Fuchs is using an optimized Android™ Industrial+ operating system. The OS impresses with especially high safety standards and long-term availability, and provides a user interface that will be familiar for many users due to its parallels with the well-known smartphone OS.

Alongside the introduction of the basic device and the various RFID read/write heads, Pepperl+Fuchs has expanded its portfolio to feature the associated accessories. This includes long-life lithium-ion replacement batteries with a 6,000 mAh charging capacity, and a charging/docking station that allows the handheld and a replacement battery to be charged at the same time. The docking station has a USB-A port with a host interface. For example, this allows users to connect a USB stick and copy programs or read results from the handheld to the storage device.

On top of the comprehensive range of hardware, Pepperl+Fuchs is offering customer-specific software development for the new RFID handhelds. For example, this could include designing an individual user interface, dialogs or a connection to existing IT systems.

Highlights of the odular RFID Handhelds:

- Modular design consisting of basic device and read/write heads for all frequencies

- Plug-and-play concept enables simple and fast module replacement

- Future-proof due to modern Android™ Industrial+ operating system

- Powerful processor and RAM offer high performance in complex applications

- Large 4.8″ TFT color display and demo software for convenient operation

- IP54 degree of protection for industrial use indoors and outdoors