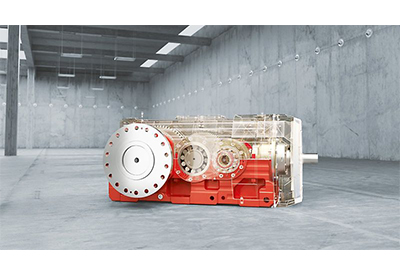

New Sinamics G120X Drive Series Specializes in Infrastructure Pump, Fan and Compressor Applications

With power range from 1–700 hp (0.75–630 kW), Sinamics G120X drive is optimized for pump, fan and compressor applications

June 12 2023

Siemens is introducing the new Sinamics G120X drive, a simple, seamless and easy-to-use drive, designed for use in pump, fan and compressor applications in industries such as water/wastewater, HVAC/R, irrigation/agriculture and in industrial environments. Sinamics G120X has a power range of 1–700 hp (0.75–630 kW) and can operate in a temperature range from -4 to +140° F (-20 to +60° C) with any standard motor, including synchronous reluctance motors (SRM). It has an integral DC choke which improves harmonics and EMC performance. Sinamics G120X meets all the latest and upcoming UL, NEMA and EN/IEC standards for 2019 and beyond and offers up to 100 kA short-circuit current rating (SCCR) ensuring enhanced product safety and energy efficiency.

Sinamics G120X easily integrates into existing applications and is configured for cost-optimization and resource-saving operation, which ultimately helps reduce total cost of ownership.

The compact design of the G120X saves space in the control cabinet and can also be easily integrated in to MCC solutions (including plug-in buckets). Even without an additional output reactor, Sinamics G120X drives enable motor cable lengths of up to 492 ft. (150 m) with category C2 or C3 filter and up to 1476 ft. (450 m) without filter and have hardware-based SIL3-certified safety functions built-in.

“The Sinamics G120X offers outstanding ‘out-of-the-box’ ease of use and is simple to commission and operate using its high-resolution graphical color keypad, known as IOP-2 (intelligent operator panel), as well as the optional Wi-Fi-enabled Smart Access wireless module — both optimized for pump and fan applications,” states Nikunj Shah, product manager, Siemens, Digital Factory, US.

Nikunj Shah, product manager, Siemens, Digital Factory, US

Shah continues, “Sinamics G120X drives offer an automatic restart function after power failures and the multi-pump/staging operation mode allows the user to control several pumps using just one drive. Its energy-saving mode automatically switches the motor on and off to save energy and reduce wear. G120X also has built-in energy functions which display energy consumed as well as energy saved.”

The G120X has Class 3C3 coating which is suitable for harsh environments where the presence of corrosive gases such as Hydrogen Sulfide (H2S) is present. A high C2 or C1 EMC category ensures the drive can be reliably used in any kind of industrial and public networks.

Sinamics G120X is compliant with all relevant EU and upcoming NEMA energy-saving standards and offers an operating efficiency level of over 98% (efficiency class IE2). Its comprehensive range of integrated application-specific functions for pumps and fans ensures improved energy efficiency through amount of actual energy needed in line with the actual load which ensures the best possible performance and minimal energy losses.

Sinamics G120X is fit for digitalization and can be linked to Mindsphere by using Sinamics Connect 300 and the Mindsphere app Analyze MyDrives. This offers users the opportunity to analyze valuable operating data gathered from the drive and enables the visualization and analysis of status information, providing users with valuable data which can be used as the basis for process optimization and maintenance strategies. Mindsphere is the cloud-based, open IoT operating system from Siemens that connects products, plants, systems and machines, while enabling a user to harness the wealth of data generated by the Internet of Things (IoT) with advanced analytics.

More Information

Related Product

Quick and Easy Simulation of Drives with SINAMICS Drivesim Basic

With SINAMICS DriveSim Basic, Siemens presents a new software solution, with which drives and their behavior in machines and plants can be simulated, adapted and optimized. With this new solution, Siemens offers a quick and easy entry into the drive simulation and enables machine and plant manufacturers to accelerate their own development phase.