New ABB actuator launches, helping improve efficiency, safety and product quality

February 18, 2020

ABB recently announced the launch of its Induction xP Plus actuator for paper and packaging manufacturers seeking a powerful, efficient, rapid-acting and safe method for controlling caliper on paper machines calenders.

Induction xP Plus rapidly ensures efficient heating up to 100 kW/meter in a highly-targeted area, providing unmatched flexibility for power density and heating zone width. It is the only caliper profiling system available with hybrid control zone configurations of 60 mm, 75 mm or 120 mm, enabling customers to target higher precision heat distribution at the edges, where it is often critical, as well as increasing heat density to get on spec quicker—even after sheet breaks.

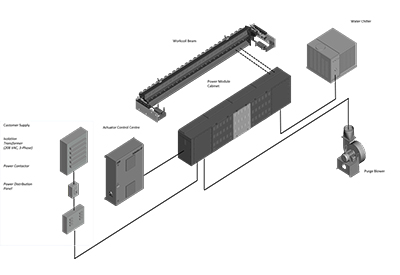

“Induction xP Plus significantly enhances our offering as the only actuator featuring ABB’s unique power module technology, hybrid zones for targeted heat distribution and flexible layout configurations,“ said ABB product manager Frank Condra. “The specification is developed to maximize paper quality and productivity, but crucially, includes an off-machine power module, enabling Induction xP Plus to meet the most stringent industrial safety requirements.”

An evolution of ABB’s highly-regarded Induction xP actuator, the new Induction xP Plus uses ABB’s uniquely efficient fixed frequency/soft switching technology which, in tandem with a lower voltage design, ensures negligible switching losses and lower stresses on electronic components. Induction xP Plus also features serial communications to the power modules, a three-phase power bus distribution system and advancements in the mower module and workcoil. These features combine to deliver the lowest CD caliper variation and associated improvements in reel build, while also providing the best sheet finishing for gloss, smoothness, and printability.

ABB’s Induction Profiler is an integral part of the ABB Ability Quality Management System, which is based on industry-leading ABB Ability System 800xA. By utilizing advanced measurement, control strategies and high-performance algorithms, ABB caliper and gloss control minimizes caliper and gloss variations under any operating conditions.