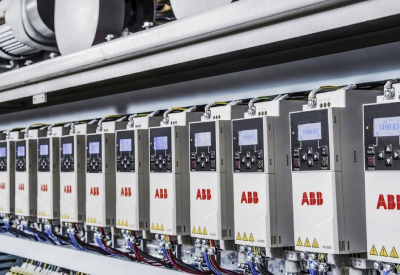

New ABB ACS180 Machinery Drives Offer Reliable Machine Operations and Essential Application Control in a Compact Footprint

November 8, 2022

- •The ACS180 enables machine builders to integrate a compact variable speed drive in a wide variety of industrial applications

- •A machinery drive that offers excellent performance and quality at superior value

- •The new drive is suitable for applications up to 22 kW

ABB has extended its all-compatible family of machinery drives with the new ACS180 variable speed drive (VSD) for applications up to 22 kilowatts (kW). This easy-to-use and compact VSD brings reliability and performance for machinery builders.

The ACS180 is designed for OEMs and system integrators across several industries and for a wide range of applications. The ACS180 can control for example: conveyors, pumps, fans, mixers, and compressors, in a wide variety of industry sectors including food and beverage, textiles, material handling, and commercial applications.

YiRan Jia, ABB global product manager, said: “The ACS180 is an important addition to our machinery drives family that establishes a solid foundation for the majority of straight forward applications. However, the ACS180 is definitely not a stripped-down version of the larger drives. It delivers a high level of performance, robustness, flexibility and functionality for machine builders who want an affordable and simple-to-integrate drive option.”

The ACS180 joins ABB’s well-established family of All-Compatible drives for machine building. It features a robust and compact design that offers precise control as well as scalability and flexibility. All-Compatible ABB drives share the same architecture and user interface for ease of use.

The ACS180 is designed for controlling both induction and permanent magnet motors ranging up to 22 kW.

The VSD is housed in an IP20 enclosure in five frame sizes for cabinet mounting. It features a robust design and optimized airflow for cooling to ensure a long and reliable service life. To provide the functional safety essentials when designing and building machines the VSD has embedded Safe Torque Off (STO) functionality that brings motor safely to a no-torque state.

When it comes to performance, the ACS180 offers excellent motor control without an encoder. It supports both scalar control for effortless, robust and basic speed control and vector control for more demanding regulation of speed and torque to ensure accuracy throughout the speed range.

The VSD can interface with an overall plant automation system via its built in Modbus RTU protocol or using digital/analog input and output control connections. Graphical icons make the built-in control panel straightforward to operate and reduces the need for translation, which is important for OEMs selling in global markets.

Adaptability to machine automation needs is provided by the ACS180’s new-generation adaptive and sequence programming that allows customization of the drive’s functionality. This uses the embedded small-scale programmable logic controller to offer a common approach to drive programming that enables the drive functionality to be tailored to suit its specific application.

For more information, click here