What To Know About Navigating the End of RSLogix 5

February 5, 2025

Review what the final lifecycle phase of RSLogix 5 programming software means for your operations and how to prepare for the future.

For nearly four decades, the Allen‑Bradley® PLC-5® and its programming software RSLogix™ 5 have been the cornerstone for industrial automation. While paving the way for future PLC and software development that is seen today, the longevity speaks to its reliability and robustness of the platform. However, as technology evolves, it must continue to evolve along with it to achieve modern business and expectations. RSLogix 5 will reach its final lifecycle phase on December 31, 2025.

Let’s highlight what this means for your operations and how to prepare for the future.

What This Means for Your Business

If you’re currently using RSLogix 5, here are the key points to understand:

- On December 31, 2025, new RSLogix 5 activations will no longer be available for purchase.

- The software has already reached End of Life status, meaning no more anomaly corrections or functional improvements

- RSLogix 5 will continue to be supported through Rockwell Automation technical support

What do you Need to do to Prepare

Consider the following whether you are looking to maintain your install base, support your customers, or modernize your platform.

- Assess your software licenses. Take inventory of your current RSLogix 5 licenses and evaluate if they’re sufficient to maintain your system.

- Have a support plan. Identify a plan for technical support by Rockwell Automation and/or your local service partners.

- Evaluate your business objectives. Use this lifecycle change to evaluate your automation strategy, including meeting your company’s technology policies or modernizing to achieve a competitive advantage.

Looking Forward to the Logix platform

As the final chapter closes on sales of one of the most popular PLC systems in history, there is much to look forward to with innovations from ControlLogix®, programming software Studio 5000 Logix Designer® and FactoryTalk® Design Studio™. A new ControlLogix controller is set to release this year with integrated safety for all controllers and enhanced system performance and capacity. The controller programming software suite continues to add functionality to deliver an end-to-end design experience to meet modern business needs and users.

With expanding device and code libraries, generative AI code development, and automated testing capabilities, the controller design software continues to evolve to allow efficient application design to improve time to market and reduce downtime. These continued functional and feature improvements to the Logix platform deliver to support the modern PLC user as we look to the future of industrial automation.

More Information

Related Story

Rockwell’s Three Smart Factory Trends that Pay Big Dividends

Rockwell Automation has seen manufacturers around the globe investing billions of dollars in smart manufacturing and production plants. Industry experts project the demand for smart factories will double by 2032 to $322 billion because of the increased return on investment.

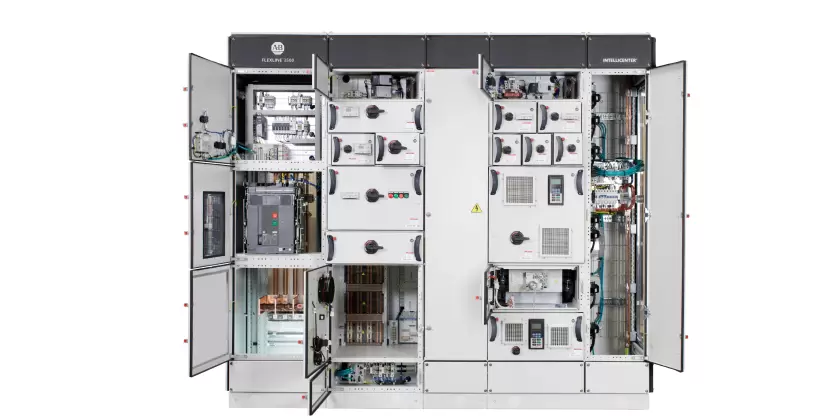

At the heart of smart factories are smart motor control centers (MCCs). These industrial control units contain networked motor control technology, power distribution and electrical switchgear to manage critical factory equipment and provide a constant flow of data from the equipment.