Mitsubishi Electric Automation, Inc. Launches R86TB High-Performance Teach Pendant for Improved Operability

February 22, 2024

The R86TB Teach Pendant can handle a series of processes from setup to maintenance, relieving the need for an on-site computer to reduce time and costs.

Mitsubishi Electric Automation, Inc.’s new teach pendant, R86T6, evolved from the conventional, high-performance teach pendant to deliver customizable and intuitive functions to OEMs and end users alike. The R86TB is designed with a 10.1-inch high-definition display so that any function can be easily visible and accessed from the customizable HOME screen or page list. Major functions of MELSOFT RT ToolBox 3, Mitsubishi Electric’s PC-based robot programming software, are accessible and equipped to provide program support functions, parameter and program screens, 3D monitoring, and more.

Additional features of the R86TB Teach Pendant include data analysis and real-time monitoring to perform trouble diagnosis, secure hardware buttons for tactile and consistent operation, improved processing speeds, and security functions. Compatible with CR800 and CR700 series Controllers, R86TB allows customers increased visibility and operability to ensure smooth operations and high performance.

“We are very confident that our customers will benefit from the enhanced functionality, durability, and performance that the R86TB provides. The large, high-definition display makes it possible to make program revisions without needing to bring a laptop onto the manufacturing floor. We have designed it to be backward and forward compatible so that it can be used on older CR700-controlled robots as well as our current and future generations of robots,” said Patrick Varley, Product Marketing Manager (Robot) at Mitsubishi Electric Automation, Inc.

More Information

Related Product

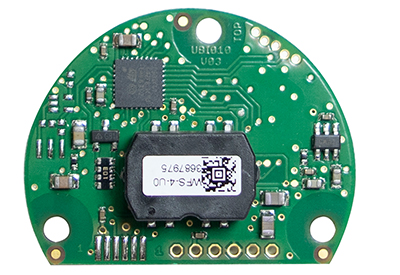

Mitsubishi Electric Automation, Inc. Launches CIP Safety Module for Safe Communication Over Devices in a Network

Mitsubishi Electric Automation, Inc. has designed the MELSEC iQ-R Series CIP Safety Module to ensure safety signal transmission to a diverse range of devices and equipment, including third-party robots, Mitsubishi Electric and third-party-VFD products, and safety I/O and interlocks. Common Industrial Protocol (CIP) safety is a protocol developed by the Open DeviceNet Vendor Association (ODVA) and is widely used in industrial automation systems. CIP Safety defines a set of rules and mechanisms for exchanging safety-related information between devices in a network to ensure reliable communication of critically safe data within an industrial system.