Mitsubishi Electric: Geared Motors Right angle shaft type

December 16, 2019

Advanced Super Helicross Series

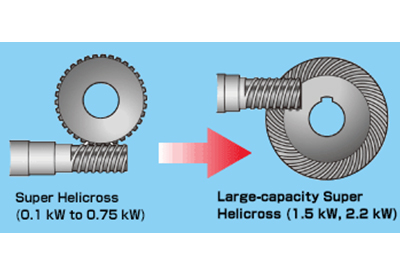

The Super Helicross series are high-precision, super-silent geared motors that mount the first right-angle “Super Helicross Gears” (0.1 to 2.2 kW) in the industry.

This product offers many features (low noise, low vibration, long life, compact design, high efficiency) made possible through the RGC processing technique and gear meshing simulation technology.

The Super Helicross series has evolved to now offer an increased capacity of up to 2.2 kW. Rotation irregularities have been prevented, to transmit power smoothly.

Reliability improved by high-quality oil seals

The results of Mitsubishi Electric’s years of research on oil seals are reflected in the product. The oil seals demonstrate their excellence in high-temperature environments and during operations with frequent switching between forward and reverse directions.

The oil seals have been developed exclusively for each motor axis, realizing an output axis that provides a sealing capacity ratio 100 times greater than conventional models.

Lineup includes wide range of specifications

Our broad lineup of geared motors allows you to choose the product best matched to your needs.

Standard specifications

Voltage: 200/200/220V

Frequency: 50/60/60Hz

Installation location: Indoor

Mounting direction: GM-SHY. SHYP: Free mounting

GM-DYP: Horizontal mounting