Mitsubishi Electric and Dispel to Expand Operational Technology Security Business

March 15, 2024

Mitsubishi Electric Corporation announced that it has signed an agreement with Dispel LLC, a developer and distributor of secure remote access and operational management solutions, to expand its operational technology (OT) security business through marketing and technical development

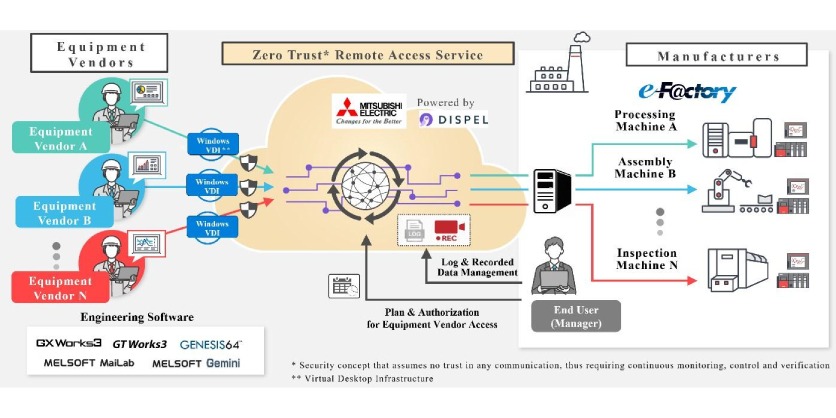

Based on the agreement, Mitsubishi Electric will integrate its factory automation (FA) equipment and OT security solutions with Dispel’s secure remote-access technology to provide a Zero Trust Remote Access Service that monitors, controls, and verifies remote-access operations involving equipment in manufacturing facilities. For Mitsubishi Electric, the goal is to accelerate digital manufacturing by utilizing data throughout entire product lifecycles, from design and installation to operation and maintenance, and thereby strengthen the company’s circular digital engineering business.

Mitsubishi Electric, a leading supplier of FA control-system equipment, provides complete one-stop OT security solutions that incorporate services ranging from assessment and consulting to countermeasures and operations. The company is dedicated to ensuring network security and reliable communication management by controlling access to OT assets and implementing traceability measures.

Dispel is a U.S. security vendor that provides secure remote-access services to critical facilities, including power and water utilities, financial companies and research institutions, primarily in North America. Dispel has technologies for access control and traceability through logging and recording based on “when, who, and where,” enabling more detailed and secure management compared to traditional VPN solutions. The company adheres to worldwide security standards, such as NIST CSF* and IEC 62443**, in its provision of remote access environments on a global scale.

“At Mitsubishi Electric, we are creating new value in OT security by combining our OT technology and expertise in manufacturing with information-system security technologies from leading security vendors,” said Kunihiko Kaga, Mitsubishi Electric’s Representative Executive Officer and Industry and Mobility Business Area Owner.

“Through our collaboration with Dispel, we expect to contribute to OT security and society as a whole by providing secure environments for remote maintenance.”

“What matters to industrial customers is uptime, availability, and crew safety,” said Mr. Ian Schmertzler, President of Dispel. “Cyber security should not be something they need to worry about, but the shifting regulatory and threat landscape has made it impossible to ignore. By providing a Zero Trust Access platform aligned with NIST 800-53 to their customer base, Mitsubishi Electric is making it possible for their clients to refocus on what matters.”

Remote maintenance, which involves utilizing internet technology to monitor and troubleshoot production lines from remote locations, is attracting increasing interest due to manufacturing’s globalization as well as its implementation of IoT and digital transformation. However, accessing factory systems via the Internet has increased security risks, such as cyberattacks targeting communication pathways, which is inhibiting the adoption of remote maintenance. In addition, large manufacturing sites typically use equipment from multiple equipment vendors, which requires a dedicated communication path for each vendor’s equipment, resulting in multiple communication paths being exposed to security risks.

More Information

For more information about the Dispel, visit https://dispel.com/

Related Story

Mitsubishi Electric Automation, Inc. Provides an Automated Machine Tending Solution that Triples Output for Customer

TL Aerotek was looking for an automated solution to keep up with accelerating demand and found success using Mitsubishi Electric Automation’s plug-and-play machine tending solution, LoadMate Plus™.