Dynamic Interactions Made Safe with Leuze

July 24, 2023

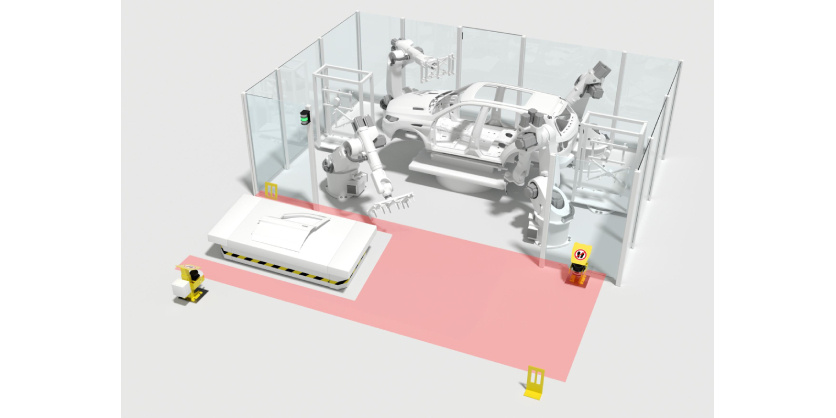

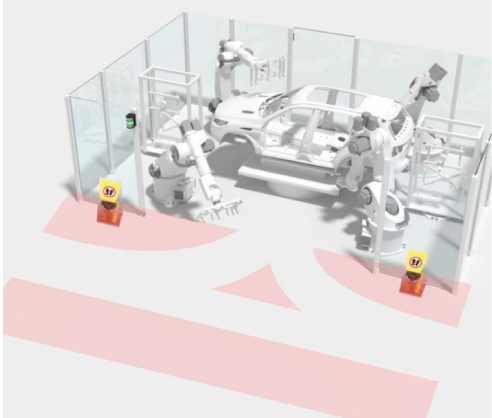

During automated material transfer between robot cell and automated guided vehicle, people must not stray into the danger zone unnoticed. An innovative solution by Leuze secures the transfer stations by means of dynamic protective field adjustment. This makes additional safety measures such as barriers and fences unnecessary.

Risk-free full automation

In smart factories, the flow of goods is fully automated. This means that production materials are made available in prepared containers on staging areas, also known as supermarkets. Digital notifications that materials are needed are sent directly from the production area. Automated guided vehicles (AGVs) are used to supply the robot cells with the required parts and to collect the processed components.

The automated processes at these transfer stations, where AGVs interact with robot cells, must be designed so as to be both risk-free and efficient. This can be realized only with reliable safety solutions: AGVs traverse the danger zones without the robot cells interrupting their work, and people must not enter these areas unnoticed at any time. And so the Sensor People at Leuze have developed an innovative safety concept that is tailored to such transfer stations in smart production environments. The approach is based on dynamic protective field adjustment around the AGV during the transfer of materials.

Systems must work together

Automated material transfer between AGV and robot requires comprehensive consideration of the safety functions at the transfer stations. This encompasses the entry of the AGV into the station, the reaching of the transfer position, and the exiting of the station. The AGVs themselves are secured by means of their built-in sensors—through safety laser scanners for instance. And the robot cells are equipped with sensors that recognize whether a person is approaching the hazardous work area.

But for automated material transfer between AGV and robot, the different control units of the systems involved in the process (robot cell, AGV, and material flow control) must be able to communicate with each other. Moreover, they must be coordinated in such a way as to guarantee safety and reliability throughout the entire cycle. This can be realized only through close coordination between the various departments involved. In addition to (factory) planners, logistics managers, and occupational health and safety officers, the IT department also makes a substantial contribution to success in this phase.

Requirements for fully automated transfers

Traditional approaches often work with light curtains to secure access to the transfer area between AGV and robot cell. Although this is technically feasible, it has limited capabilities: the presence of people inside the transfer area cannot be automatically monitored. To keep people out of the danger zone, these classical concepts require further safety precautions—such as mechanical separators like fences and barriers. A fully automated, secure transfer between AGVs and robot cells without physical barriers is a more efficient solution. However, the system must be able to reliably distinguish people and AGVs.

For this approach, the following conditions must be in place:

- The danger zone of the AGV transfer station must be secured during the entire process.

- Defined AGVs should be able to travel through and exit the work area axially (optional: radially also) in a fully automated manner.

- Persons or other deviations from the defined AGV contour must be recognized at all times, triggering a secure stop signal.

AGV surrounded by protective fields

The solution developed by Leuze for safeguarding robot/AGV transfer stations guarantees two safety functions:

- Stopping the dangerous movement of the robot cell

- Dynamic adjustment of protective fields around the AGV

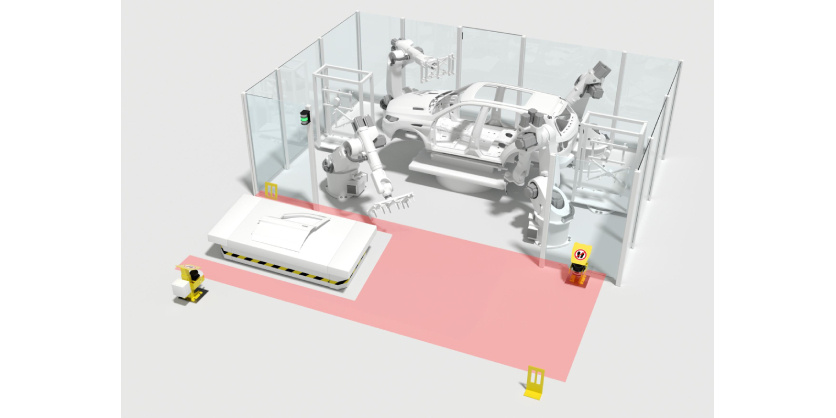

To secure the entire area of the transfer station, Leuze utilizes safety laser scanners. These scanners use protective fields to detect the entry and presence of persons in the transfer area. When this happens, the system triggers a stop signal. In a parallel process, the position of the AGV in the monitored zone is recognized at all times. So that the AGV itself does not trigger a stop signal, the safety program masks out its contour from the secured zone. The protective field thus adjusts dynamically around the moving AGV.

To this end, the laser scanners incrementally shift their preconfigured protective fields. This allows the AGV “enclosed” by protective fields to automatically travel into the station, transfer the material at the parking position, and then exit the station again. The safety level is maintained during the entire cycle. This has the advantage that the rest of the environment is covered at all times by the remaining protective field—offering all-round protection. As a principle, only the AGV contours defined in the system in advance are capable of crossing the protective field. In order to detect tampering or scanner misalignment, Leuze uses the spirit level function built into the device as well as additional external reference contours.

Axial or radial entry possible

Only a few components are needed for Leuze’s safety solution, including two RSL 400 safety laser scanners, which are noted for their excellent performance, robustness, and easiness to handle. With their high operating range of 8.25 meters, they are able to monitor even large areas. The solution is rounded off by a safety program from Leuze and by the Siemens SIMATIC S7 system control. Optimal positioning of the RSL 400 laser scanner in the application depends on various factors which must be taken into account:

- Application layout and potential shadowing due to the design

- AGV specifications (such as dimensions)

- Entry and exit positions of the AGV into/from the protective field

- Transportation paths and speed of the AGV in the protective field (axial and/or radial)

Depending on the above, a diagonal or linear positioning of the laser scanners around the protective field may be preferable. In special cases (e.g., involving corner layouts with shadowing from the building or cell structure), the system can also be operated with more than two laser scanners.

Easy to implement

For this smart type of safeguarding, only a handful of requirements must be met, such as the minimum width of the AGV and the maximum travel speed in the protective field. In addition, the route accuracy of the AGV should be around 50 millimeters. Furthermore, there must be sufficient space available in front of the danger zone in order

- to be able to maneuver the AGV in the space and

- to be able to implement a sufficiently large scanner protective field (required minimum distance to hazards from all access sides).

To initiate an entry or crossing of the AGV, the material flow control’s AGV guidance system must report its route in advance to the safety solution. Depending on the risk assessment for the application, it can be necessary in the case of a protective field violation to stop the AGV in addition to stopping the robot cell. This presupposes secure communication between the cell and the AGV.

Flexibility with transport material

With this concept for securing robot/AGV transfer stations, system operators receive a cost-efficient solution that offers fully comprehensive safety throughout the entire cycle. It fulfills Performance Level d according to ISO 13849-1 and SILCL 2 according to IEC 62061. This means that accident risks can be reliably minimized. The safety solution from Leuze works autonomously after the AGV has been registered through the AGV guidance system. And it offers maximum flexibility, with no restrictions during part transfer.

The safety system and the protective fields work based on the contour of the AGV and not on the material being transported on it. Even parts sticking out the front or the sides are transported reliably. Furthermore, the integration makes mechanical safeguards such as fences and barriers superfluous. This saves valuable space in production.

From risk assessment to results

Any business that wants to implement this concept for its automated system needs an experienced partner at its side. It is important here that the entire process is accompanied by the provider of the safety system. In this way, a customized solution can be devised and implemented. The first step is risk assessment: the dangers (e.g., in the robot zone) must be clearly defined. It must also be known how quickly the robot cell stops. On this basis, the size of the protective field and the timing of actions can be defined.

The Sensor People from Leuze are the right contact partner for these steps. They assess the situation on site, determine the requirements, and develop a safety concept. After installation of the components, Leuze provides support with the corresponding documentation and with sensor parameterization and commissioning. The service offer also includes a final validation of the application. And last but not least, CE conformity provides legal certainty. This allows businesses to reap the benefits of innovative material logistics systems without compromise.