Kollmorgen Expands AKD2G Versatility with Launch of New Synchronized Communication Protocols

March 26, 2024

The updated Kollmorgen AKD2G servo drive features new communication protocols that support easier integration with third-party controllers while delivering industry-leading performance

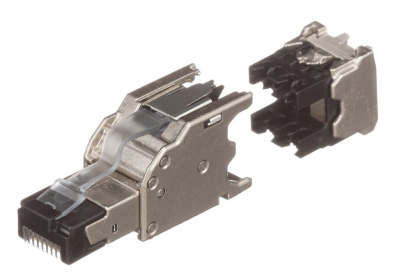

Kollmorgen, a global leader in motion control systems, has announced the latest update to its AKD2G servo drive. With the introduction of these new features, Kollmorgen has broadened its offerings to additionally support PROFINET IRT and Ethernet/IP with CIP Sync alongside CANopen®*, EtherCAT®*, and FSoE time-synchronized communication protocols. Each protocol is rigorously tested with a variety of motion controllers and certified by industry standards organizations.

The AKD2G servo drive update allows for synchronized motion between multiple drives using a wide variety of control architectures. Thanks to its flexibility and high performance, AKD2G is the ideal drive for use in applications that require highly precise coordination across multiple axes of motion.

The drive features industry-leading power density in a compact package and is easy to mount — with one- and two-axis variants available. Engineers can leverage single-cable Smart Feedback Device (SFD) or HIPERFACE®* DSL connections, or choose from a wide range of other feedback devices.

Finally, the drive features an optional SafeMotion®™ Monitor (SMM) firmware with a safety level of SIL3/PLe to meet functional safety needs and enable a wider range of applications.

“The AKD2G servo drive is an ideal option for automation designers and OEMs that are actively optimizing their designs — offering increased performance, a smaller footprint and greater design flexibility,” said James Davison, Senior VP/GM at Kollmorgen. “It’s a system designed with our customers in mind to make automation engineering easier, more efficient and more powerful.”

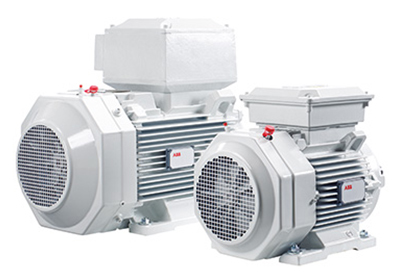

The AKD2G paired with AKM2G motors is part of the 2G Motion System, a suite of motion products designed to work together for ultimate ease of setup and higher performance.

Engineers also can take advantage of the drive’s compatibility with a wider range of controllers and feedback devices — or with other motors, as needed.

More Information

Related Story

Kollmorgen Express Delivery Significantly Shortens Lead Times for the Company’s Most Popular Motion Products

Kollmorgen, a global leader in motion control systems, has announced the launch of Kollmorgen Express Delivery. This new designation identifies highly popular motion products — including some of the most-requested configurations and options — that Kollmorgen is ready to deliver within an accelerated timeframe.