IO-Link Safety: Communicate Safely at Field Level – In One System

November 14, 2023

With IO-Link Safety, the non-proprietary, standardised communication system IO-Link is now also available for functional safety

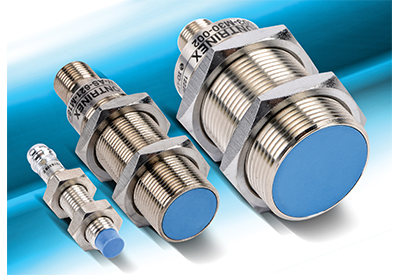

With IO-Link Safety, the non-proprietary, standardised communication system IO-Link is now also available for functional safety. Safe, standardised point-to-point communication enables safety sensors and actuators to be integrated into any existing fieldbus system. IO-Link Safety is standardised worldwide in IEC 61139-2 and offers maximum safety up to PL e of EN ISO 13849-1 (or SIL 3 of IEC 61508/62061).

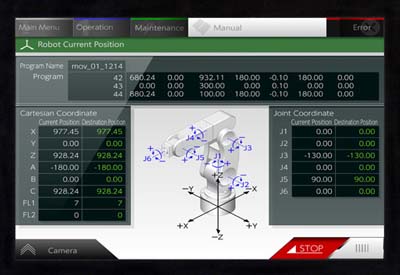

As an expert in safe automation, at SPS 2023 Pilz will be presenting something new on the market: a complete IO-Link Safety System with Master and sensors. Alongside the first devices with IO-Link Safety functionality, such as the safety light curtains PSENopt II advanced IOLS and the control unit PITgatebox IOLS, they will also be presenting their IO-Link Safety Master PDP67 IOLS. An economical and flexible complete solution, which simplifies integration into plant and machinery, and increases performance.

As the interface to the safety controller, the IO-Link Safety Master enables bidirectional communication up to field level. Alongside IO-Link Safety devices, IO-Link sensors and actuators as well as classic safety sensors can also be connected. The IO-Link Safety sensors supply important status information and offer more options in the field of intelligent diagnostics. The devices can be identified and parameterised automatically, which makes them easier to swap and reduces downtimes.

The Benefits:

- Reduce costs and increase productivity:

- IO-Link Safety devices are identified automatically and parameters are adopted directly. This makes it easier to swap components and reduces plant and machine downtimes caused by repairs. Also, fewer device types are needed, thus reducing complexity in purchasing and creating space in the warehouse.

- Innovative machine concepts:

- Seamless communication with each sensor and actuator enables intelligent data evaluation. This expands the possibilities for developing networked plant and machinery; with IO Link Safety up to sensor level, aspects such as Industrie 4.0 can be implemented very simply, independently of the manufacturer.

- Shorter commissioning times:

- IO-Link Safety communication occurs via unshielded cable and uses standard industrial connectors. This saves time and money when swapping devices.

- Economical maintenance:

- Intelligent IO-Link devices offer diagnostic functions. That enables new, predictive repair and maintenance concepts

More Information

Would you like to learn more about the possibilities of IO Link Safety?

Then visit Pilz at SPS in Hall 9, Stand 370, and experience the first, complete IO Link Safety System. In their presentation entitled “IO Link Safety – Intelligent, safe communication up to field level”, you’ll also hear some interesting information about IO-Link Safety functionality.

Can’t attend? Visit Pilz

Related Story

Pilz Is Expanding Its Worldwide Online Training Offer: Machinery Safety Knowledge – Live, From Anywhere

The automation expert Pilz is expanding its worldwide digital training offer for machinery safety. With the new “International Training Calendar”, standardized training courses from Pilz can now be attended live online. So, the training offer is also available in regions where Pilz does not have a subsidiary. As a result, Pilz makes it easier for customers to access knowledge sharing and gives them greater flexibility for further training in key areas of machinery safety.