Introducing the dV Sentry® Filter: The Future of Motor Protection

September 26, 2024

In the quest for superior motor protection, MTE has unveiled a groundbreaking innovation: the dV Sentry® dv/dt filter. Designed to revolutionize motor protection in even the most challenging environments, the dV Sentry® combines advanced technology with unparalleled performance to offer the ultimate solution for safeguarding your motors.

The Next Generation in Motor Protection

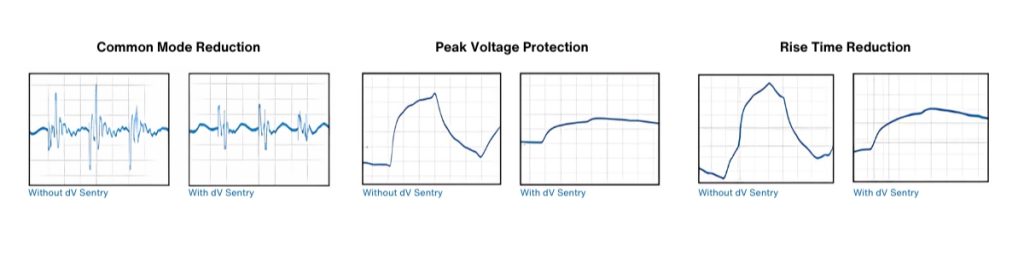

The dV Sentry® is more than just a filter—it’s a leap forward in motor protection technology. With its patented design, this cutting-edge filter stands out in the market by delivering three critical benefits in one compact unit:

These features work together to provide superior protection for your motors, ensuring longer operational life and enhanced performance.

Why Choose the dV Sentry®?

- Unmatched Protection: The dV Sentry® filter is the first proven solution that integrates common mode reduction, peak voltage protection, and rise time reduction into a single unit. This advanced technology translates to greater motor protection and reliability over time.

- Compact and Robust Design: The dV Sentry® features a small, flat design that makes installation straightforward and efficient. Despite its size, it’s built to withstand harsh conditions and challenging environments, ensuring long-lasting performance.

- Low Heat and Noise: Unlike previous filters, the dV Sentry® runs quietly—comparable to a normal conversation—and radiates less heat, contributing to a cooler and more efficient operation.

- Efficiency and Reliability: With a low watts loss, the dV Sentry® minimizes heating in systems, while its high efficiency and robust design ensure reliable operation in diverse conditions.

- Extended Warranty: To back its performance, MTE offers a three-year warranty, underscoring our commitment to quality and customer satisfaction.

Performance Specifications

- Input Voltage: 208V – 600V +/- 10%; 60Hz

- Current Range: 3A – 600A (2 HP – 600 HP)

- Inverter Operating Frequency: Up to 90Hz without derating; Up to 120Hz with derating

- Maximum Ambient Temperature: -40°C to +60°C (modular filter), -40°C to +50°C (enclosed filter)

- Insertion Loss (Voltage): 1.7% @ 60Hz; 2.6% @ 90Hz

- Efficiency: >99%

- Altitude Without Derating: 3,300 feet above sea level

- Maximum Motor Lead Length: 1,000 feet

- Relative Humidity: 0% to 99% non-condensing

- Current Rating: 100% RMS continuous, 150% for 1 minute, 200% for 10 seconds

- Carrier Frequency Range: 3A – 110A; 900Hz – 10kHz (up to 14kHz with derating), 130A – 600A; 900Hz – 5kHz

- Motor Audible Noise: Less than 65dB

- Rise Time: Less than 0.1 µs

- Peak Voltage: 150% of DC bus voltage up to 1,000 feet

- Common Mode Reduction: 50%+ peak current reduction typical

Conclusion

The dV Sentry® dv/dt filter represents a significant advancement in motor protection technology. By offering true common mode reduction, peak voltage protection, and rise time reduction in one innovative unit, it sets a new standard for motor protection. Whether you’re operating in extreme environments or simply seeking the best protection for your motors, the dV Sentry® is the solution you need.

Not sure which dV Sentry® filter you need? Don’t hesitate to contact Vanco at sales@vancoelectrical.com or call them at (905) 305-7702.

Check out their Product Selector Tool to help determine which filter is right for your application.

Related Story

Pioneering a Service-First Approach for Drive Integrator Partners

Vanco’s mission revolves around putting their drive integrator partners first. They are committed to supporting them every step of the way, ensuring they have access to the best products and expertise in the industry. When it comes to products upstream of the Variable Frequency Drives (VFD), Vanco has you covered. Their inventory includes high-speed fuses (Class T, High-Speed J), disconnects/overcurrent devices, and RFI filters—all actively stocked for your convenience. But that’s not all; they also offer capacitor banks, distribution panels/gear, active and passive harmonic filters, surge protection with a lifetime warranty, and custom transformers to meet a wide range of needs.