IIoT Solutions for Industrial Communication in Process Industries

May 9, 2023

IIoT solutions for industrial communication in process industries. Pepperl+Fuchs has been active in the Industry 4.0 platform founded in 2013 from the very beginning. In 2015, the company played a decisive role in the development of the Industry 4.0 Reference Architecture Model (RAMI), which describes the structured approach and communication basis for Industry 4.0.

Under the term “Manufacturing-X”, the stakeholders of the Industry 4.0 platform are now striving for the next level. According to the German Federal Ministry of Economic Affairs and Climate Action, the goal of this initiative—not least a “lessons learned” from the supply shortages during the pandemic years—is to digitize supply chains in industry: “Companies should be able to use data sovereignly and jointly across the entire manufacturing and supply chain. This allows digital innovations for greater resilience, sustainability, and competitive strength.”

Industrial Communication in Process Plants—A Great Challenge

Here again, Pepperl+Fuchs makes a significant contribution with various technologies, based on its high and long-standing expertise in explosion protection, especially for the process industry. Plant layouts with sometimes enormous spatial expanses (and cable lengths) and certain requirements for explosion protection present special framework conditions for the transfer of high volumes of data. At this year’s Hannover Fair, Pepperl+Fuchs shows a case study to demonstrate how this task can be solved on the basis of smart explosion protection technologies and the connection of smart mobile devices including IIoT applications.

Case Study: Troubleshooting 4.0. The use case “Troubleshooting in the field via remote support” is demonstrated on the model of a chemical process plant.

Industrial Communication enables real-time communication and reliable transmission of data from the field to the control level. One use case is seamless and effective troubleshooting. A mobile worker receives an error message via Ethernet-APL on the Smart-Ex® 03 smartphone with 5G. Using the identifier, the mobile worker can check which component sent the error message and gets access to valuable field device data. With the stock manager, asset management and spare part ordering is possible from anywhere in the field.

Smart Explosion-proof Technology in the Field of Process Plants

A field device connected to a FieldConnex® Ethernet-APL rail field switch reports an error to the plant’s asset management system via the cloud. Since the fault cannot be corrected by remote control, a technician equipped with the Visor-Ex®, consisting of smart glasses, the intrinsically safe smartphone Smart-Ex® 03 and a CPU pocket unit, makes his way to the field of the process plant.

Throughout the process, he is continuously connected to a team of remote experts via the plant’s own 5G campus network. They not only guide him in troubleshooting and repair, but also ensure lone worker protection. In the process, the experts see exactly what the technician sees on site, thanks to the smart glasses.

The Digital Nameplate—the Access to any Available Information

The fault is in one of three valves, all of which are equipped with a “unique identifier”. This is a unique identifier standardized in accordance with IEC 61406 for each individual serial number in the form of a QR code. The technician scans the QR code of one of the three valves with the Smart-Ex® 03 and reads out the digital nameplate of this device: this gives him access to the Asset Administration Shell (AAS) of exactly this field device.

It turns out that the error must be in one of the other valves. So he scans the digital nameplate of the second valve—now the Smart-Ex shows the error message. The data and spare parts list of the defective valve are now provided via the Asset Administration Shell. The technician has the necessary spare part with him, replaces it and orders it immediately with one click.

The demonstrator shows that with the appropriate technologies, end-to-end digital connectivity all the way to the cloud can easily be implemented in hazardous areas.

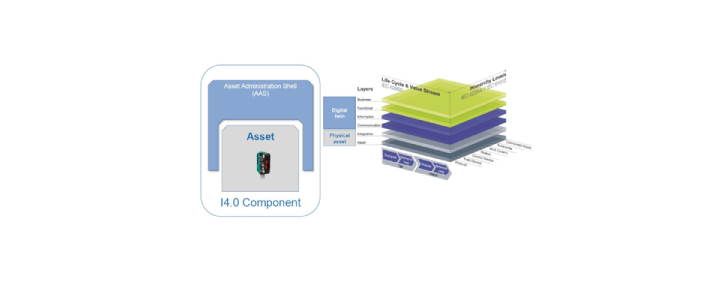

The Asset Administration Shell: the Backbone of Industry 4.0

The central element of such a scenario is the Asset Administration Shell (AAS)—the industry-neutral standard according to IEC 61360 for the supply of information of a device (asset) as well as for uniformed communication. Each asset has its own AAS, which stores information about its properties and capabilities such as construction plans, product data, changes in condition, etc. from the beginning of product development throughout the entire life cycle.

The AAS therefore represents the digital twinof the mostly physical object or asset. Via its AAS, each asset can be identified and addressed worldwide. Via standardized interfaces and a uniformed language, people or machines can find, exchange, and store all desired data and information on a specific asset—this ensures global interoperability and paves the way for digital value networks.

Unique Identifier: Key to Asset Administration Shell and Digital Nameplate

Based on the unique identifier standardized in the IEC 61406 standard, the AAS of physical objects can be accessed automatically. The digital nameplate is a unified submodel of the AAS which makes all relevant information as well as certificates and documentation available digitally. Compared to the conventional analog nameplates, the AAS and digital nameplate create considerable added value.

The initiative for the unique identifier was launched as the “Auto-ID” project by manufacturers of process equipment and operators of process plants. The goals were to accommodate the increasingly extensive marking on equipment for explosion protection, as well as to electronically manage the corresponding information of the equipment and to be able to use it digitally in the field.

Highlights

- Pepperl+Fuchs: Pioneer and co-designer of the Industry 4.0 platform

- Technology leader with more than 70 years of experience in electrical explosion protection

- Future technology Ethernet-APL brings Ethernet into the field of the process plant

- Explosionproof mobile devices from the Pepperl+Fuchs brand ecom allow data transfer, remote access, and remote support in the field

- Versatile, high-performance portfolio, software and integration expertise enable end-to-end digital connectivity all the way to the cloud

More Information

IIoT Solutions for Industrial Communication

Related Product

High Availability Cloud Connectivity for Sensors: IO-Link Masters by Pepperl+Fuchs Are AWS Partner Qualified Devices

Publishing process and status data from sensors to cloud applications in manufacturing plants is one of the key requirements for the IIoT and Industry 4.0 principles. With the official qualification of the ICE2 and ICE3 IO-Link masters as “AWS Partner Devices”, Pepperl+Fuchs is consolidating its position as a leading provider of IIoT sensors and connectivity, offering users in the AWS ecosystem access to a broad portfolio of sensors for their predictive maintenance and condition monitoring applications. These sensors can be integrated easily to AWS-based applications via MQTT or OPC UA, enabling measurement and status data to be processed in a cloud-based data historian.