Highly Flexible Cables for Drag Chain Systems and Open Installation

November 14, 2023

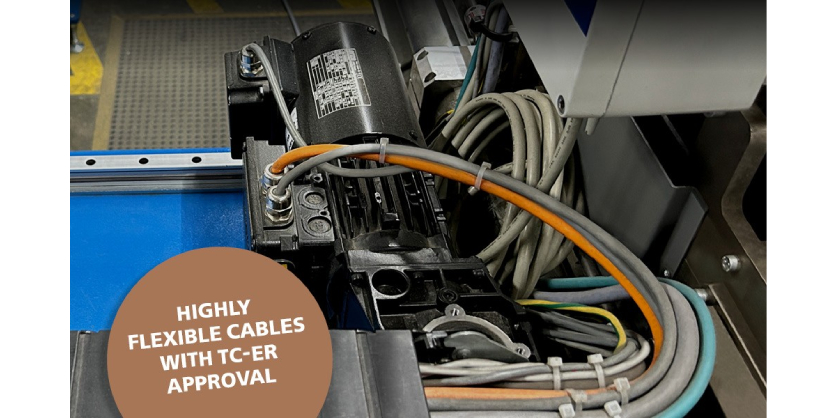

HELUKABEL has control and drive cables in its portfolio that combines TC-ER-compliant flame retardancy and flexibility for moving applications in the drag chain.

Less installation time and lower costs: In many cases, the open installation of electrical cables without a conduit or closed cable duct offers significant advantages to the user. However, this is not always possible without the appropriate approval. For example, in the North American market cables must have a TC-ER (Tray Cable – Exposed Run) certification in order to be laid in a cable tray. In order to obtain this, both the materials used and the construction have to meet special requirements – including flame retardancy.

However, the increased flame retardancy required for TC-ER cables often comes at the expense of flexibility. As a result, the constant movement that occurs, particularly in drag chain applications, is too much for most cables. The result is reduced durability and the risk of cable breakage, which can lead to costly downtime.

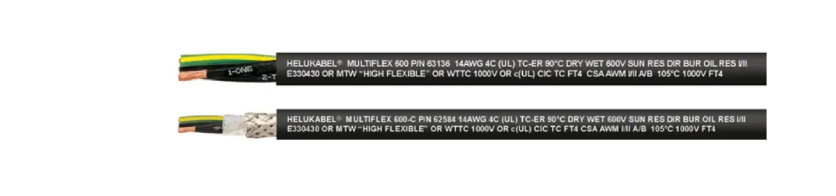

For scenarios that necessitate both TC-ER-compliant flame retardancy and a high degree of flexibility, HELUKABEL boasts two optimal solutions in its portfolio: The MULTIFLEX 600 (unshielded) and MULTIFLEX 600-C (shielded) PVC control cables. Thanks to their TC-ER approval, these cables are suitable for laying open and unprotected on the cable tray up to the machine. They are appropriately designed to be continuously flexing connecting cables in drag chains for industrial machines and systems, with a minimum bending radius of 7.5 or 10 times the cable diameter. Additionally, MULTIFLEX cables demonstrate exceptional oil resistance (Oil Res I/II) and, in the shielded version, excellent electromagnetic compatibility (EMC).

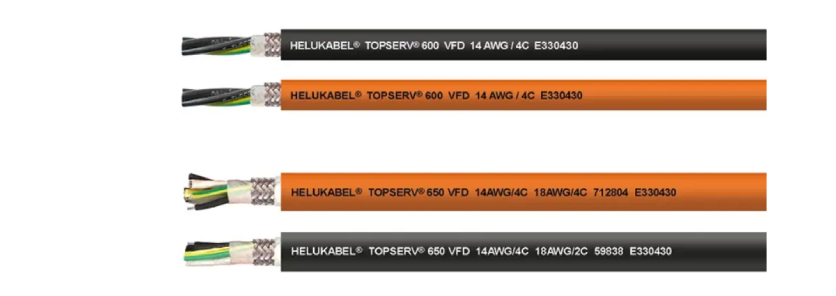

The TOPSERV 600 VFD and TOPSERV 650 VFD drive cables possess TC-ER approval and exceptional flexibility, making them ideal as supply cables for servo motors. Furthermore, a shield with a tinned copper braid offers substantial protection against electrical interference. Additionally, the special TPE jacket exhibits high resistance against oil and coolants, as well as abrasion, making it perfect for industrial applications in drag chain systems or in open-installation environments.

Both the MULTIFLEX and TOPSERV cables have been available from HELUKABEL since 2016. They have demonstrated their suitability in various applications with different demands. This offers machine manufacturers producing for the North American market a dependable solution that conforms to international standards. Together with its customers, HELUKABEL also develops individual solutions for special applications, ranging from tailor-made cables to completely pre-assembled and ready-to-install drag chain systems.

More Information

Cables with TC-ER Approval from HELUKABEL

Related Story

Why Use VFD Cables? HELUKABEL Answers

VFD cables are a critical component to extend a motor’s life cycle within a VFD system. Three areas where they set themselves apart from traditional tray-rated power ones are:

- Address high and low frequency noise issues with proper shielding

- Ability to withstand voltage spikes/reflected wave voltage

- High temperature resistance

Further enhance your electric motor’s lifespan by using EMC glands to protect your equipment from electromagnetic interference. EMC glands perform a key function in EMC protection by deflecting electromagnetic waves over the housing surface at a critical transition point – entry into the enclosure – in order to protect the exposed cable(s) inside. Thanks to their enlarged contact surfaces, EMC cable glands improve conductivity between the cable shield and gland on the enclosure housing and improve VFD cable perfromance and protect your equipment from the harmful effects of electromagnetic interference