Glebar to Showcase New Grinding and Wheel Dressing Technology at IMTS 2024 Booth 23707

August 20, 2024

MMT to highlight its precision Glebar centerless and Tridex electrochemical grinding and cutoff equipment solutions at IMTS 2024

Medical Manufacturing Technologies, Inc. (MMT) will highlight its precision Glebar centerless and Tridex electrochemical grinding and cutoff equipment solutions at IMTS 2024, Booth 237307 in the North Building from September 9-14 in Chicago, IL. The company will showcase the Tridex DM-12 CNC Grinding Wheel Dressing Machine, the Tridex CS1-E Burr-Free Electrochemical Cutoff Machine, and the Glebar GT-610 Centerless Grinder integrated with a high-accuracy five-axis pick-and-place robot, demonstrating advanced capabilities in grinding technology.

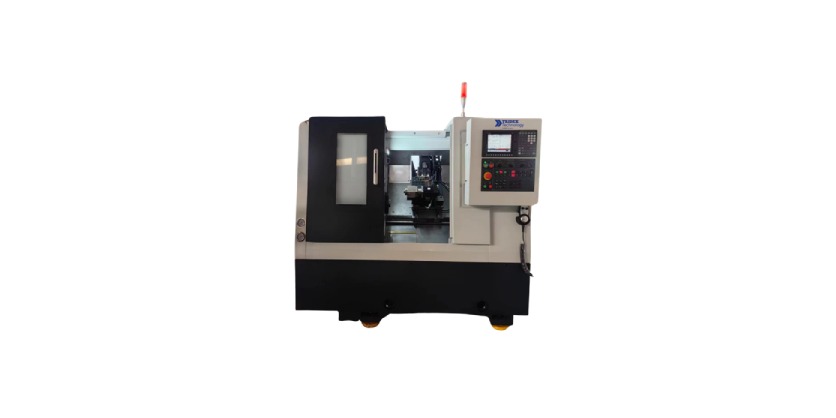

MMT recently announced the launch of its latest innovation, the Tridex DM-12 CNC Grinding Wheel Dressing Machine. This advanced machine sets a new standard in precision off-line grinding wheel dressing, offering unmatched capabilities and seamless integration into manufacturing processes. Capable of dressing wheels up to 12” (310mm) in diameter and 9.4” (240mm) in width, the DM-12 accommodates various wheel sizes, providing unparalleled versatility for a wide range of applications.

“We are thrilled to unveil the Tridex DM-12 CNC Grinding Wheel Dressing Machine,” expressed Robbie Atkinson, Chief Executive Officer at MMT. “This machine underscores our dedication to providing state-of-the-art solutions that empower manufacturers to achieve exceptional throughput and precision in their grinding processes.”

The DM-12 is designed as a standalone solution, offering off-line precision dressing for wheels up to 12” (310mm) in diameter and 9.4” (240mm) in width. This versatility allows manufacturers to achieve optimal performance across various grinding applications. Its interchangeable arbors ensure compatibility across all in-feed, thru-feed, and OD/ID grinders using wheels within the size envelope.

One of the standout features of the DM-12 CNC is its ability to handle aggressively hard electrochemical resin bonded wheels used on Tridex ECG Grinding Machines. This capability makes it an indispensable tool for industries requiring high precision and efficiency in their grinding processes.

The DM-12 CNC enables users to shape wheels offline, allowing for uninterrupted production and optimizing grinder efficiency. Its fully CNC-controlled system ensures precise dressing of custom wheel geometries, guaranteeing utmost accuracy and consistency in every operation.

For more information about the Tridex DM-12 CNC, the Tridex CS1-E, the Glebar GT-610, or other advanced grinding solutions from MMT, please visit us at IMTS Booth 237307 in the North Building, our website Glebar.com, or email sales@mmt-inc.com.

About MMT

Medical Manufacturing Technologies (MMT) is a vertically integrated business serving the medical device manufacturing industry and beyond. The company offers process development, applications and equipment, technical solutions, and aftermarket support. MMT brands include CATHTIP, Engineering By Design, Glebar, Interface Catheter Solutions, MMT Automation, MPT Europe, R&D Engineering, SYNEO, Somex Automation, and Tridex.

More Infromation

Related Story

MMT Promotes Crew Feighery To Senior Vice President, Commercial Sales and Marketing

Medical Manufacturing Technologies, Inc. (MMT), a leading global provider of medical device manufacturing solutions, is pleased to announce the promotion of Crew Feighery to the position of Senior Vice President (SVP). In his new role, Crew will be responsible for overseeing MMT’s technical and field sales, as well as marketing.