Find the Right Safety Relay with Pilz

January 28, 2025

The modular safety relay myPNOZ compliments Pilz’s existing range of safety relays. But when do you use myPNOZ? And when is PNOZsigma the right choice? Learn how to find the right safety relay.

Find the right PNOZ safety relay for your application!

Looking for the optimum PNOZ safety relay for your application? Want to make your automated plant safer? Then discover the perfect solution right now, in just a few steps!

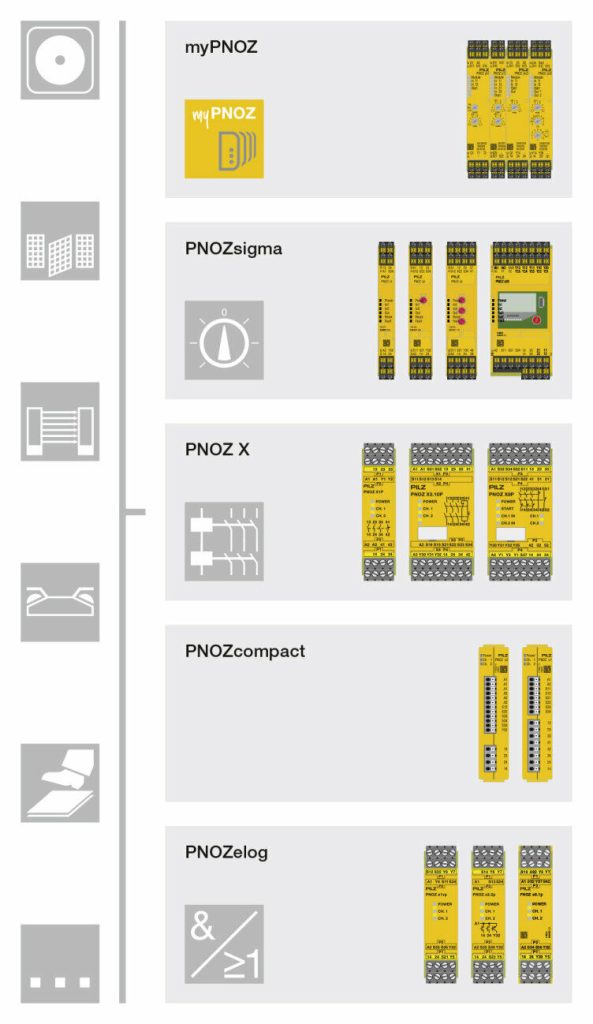

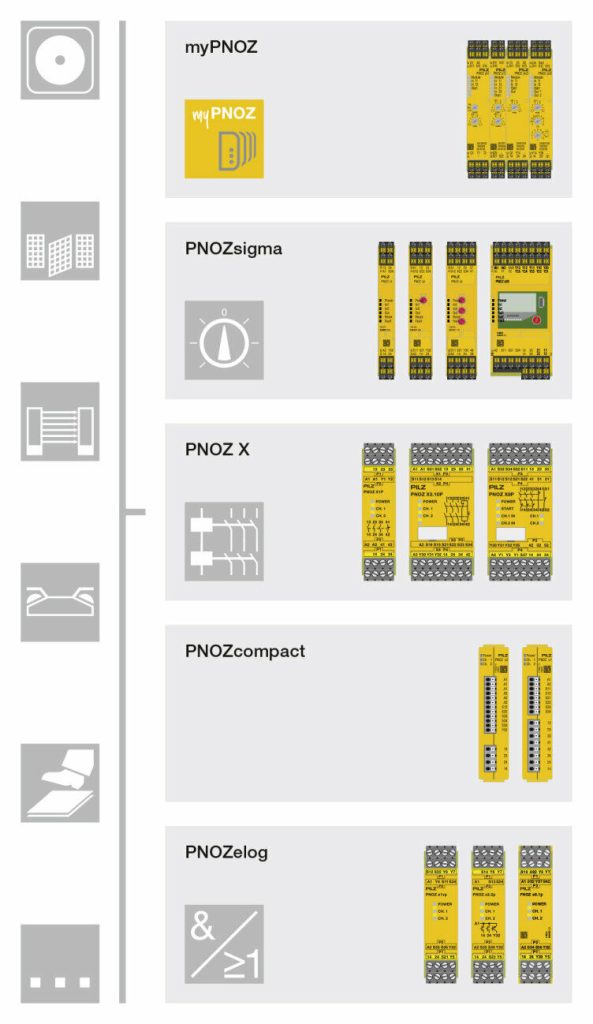

The features of Pilz’s safety relays at a glance

Pilz’s safety relays are distinguished by a variety of supply voltage ranges, the number of safety contacts, the number of terminals or the ability to plug in terminals.

Based on their different features and functionalities, Pilz’s products can be divided into the following product groups:

myPNOZ

- Safety relay with an internal combination logic

- Created individually in myPNOZ Creator

- Tailor-made in batch size 1

- Quick and easy commissioning

PNOZsigma

- Maximum function in a minimum width

- Adjustable operating modes and times

- Scalable thanks to a modular design

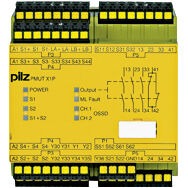

PNOZ X

- Safety for every function

- Electromechanical, floating

- With wide-voltage power supply unit

PNOZcompact

- Square, simple, yellow

- Ideal for high-volume series machine manufacturers

- Basic function of a safety application

PNOZelog

- Easy to link

- Non-wearing

- Expanded diagnostics

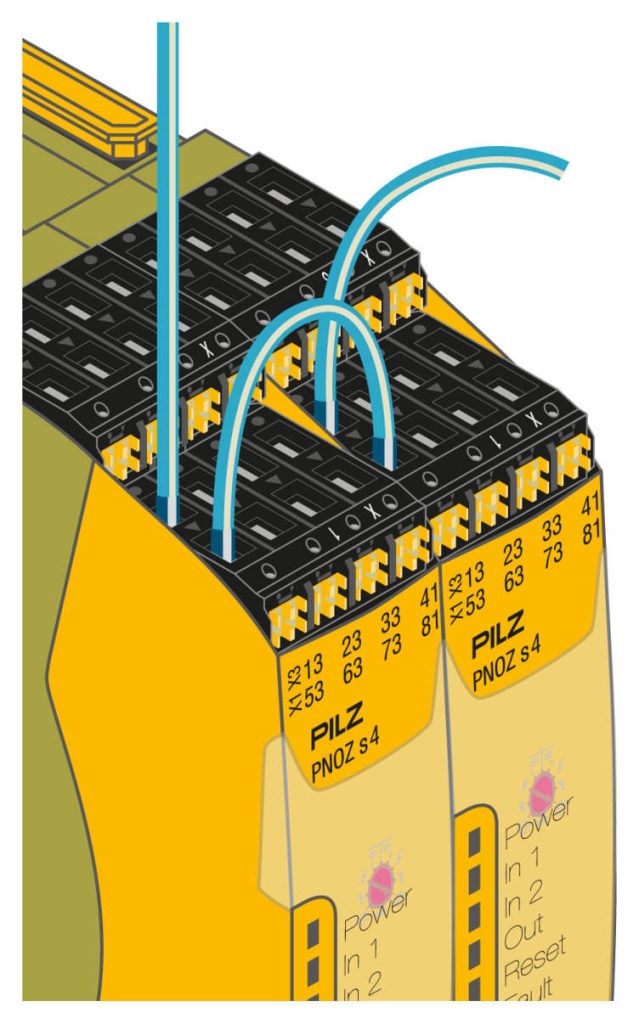

Save costs with push-in technology

The unit types with push-in technology offer a great advantage in terms of both economy and safety. They help you to cut costs due to short commissioning and service times.

The following product ranges are available with push-in, spring-loaded terminals:

- Safety relays PNOZsigma, PNOZ X, PNOZcompact, PNOZelog

- Monitoring relays PMDsigma

- Line monitoring devices PLIDdys

- Modular safety relay myPNOZ

- Small controllers PNOZmulti 2, PNOZmulti Mini, PNOZmulti

Easy to service through simple operation

- Connection of all commercially available cables with or without wire-end ferrule

- Quick and easy wiring

- Double connection option per pole; can be opened individually or both at the same time (beneficial when installing or changing the wiring)

- Cost savings when replacing devices, since no rewiring is required and potential wiring errors during rewiring are eliminated

- Separate opening for voltage testing

- Coded plugs for easy and unmistakeable installation and increased handling safety during servicing

- Maintenance-free due to defined clamping force; unlike screw terminals, no need to retighten regularly; no follow-up costs due to retightening of the terminals

- High contact reliability even against strong vibrations and shocks

- Further looping of potentials possible without any problems

The optimum safety relay for every application

In addition to the classic E-STOP function, the safety relays now monitor safety gates, light barriers, two-hand controls, pressure sensitive mats, muting, standstill, speed and many other safety functions.

Pilz’s Product Range: Safety Relays

|

PNOSsigma safety relay / safety relays |

|

PNOZ X safety relays |

|

PNOZcompact safety relays For manufacturers of production machines with high unit output, recurring standardized functions and for monitoring E-STOP, safety gates or light barriers/light grids. More Information |

|

PNOZelog safety relay/safety relays Easy to link and wear-free, with extended diagnostics: Pilz’s safety PNOZelog. More Information |

|

Line monitoring devices Line monitoring devices provide a special circuit protection or connection test, to guarantee that a signal is unambiguous As a result, faulty wiring, errors, or tampering can be excluded. More Information |

|

Modular safety relay myPNOZ Easy-to-use, modular safety relay with an internal combination logic for monitoring emergency stop, safety light curtains, or two-hand controls IIIA/C for example in small to medium applications with 2 to 30 safe input functions. More Information |

More Information

Do you need further information? Read more in chapter 5.1. The German-language Safety Compendium contains the latest knowledge on machinery safety.

Related Story

Training Courses on Plant and Machinery Safety from Pilz

Plant safety is vitally important for the safe operation of technical plants. As a machine manufacturer or operator you are legally obliged to ensure the safety of plant, machinery and devices. Training courses teaches you to identify risks and avoid accidents. Further training for safety officers and employees is the key to success here. With this knowledge you can operate plants more efficiently and safely carry out maintenance work.

By integrating plant safety into your company you are demonstrating responsibility and increasing the confidence of authorities, employees and the public. Plant safety also contributes towards the prevention of environmental pollution and damage.