Festo Introduces a Robust Suite of Pneumatic Safety Solutions

November 27, 2024

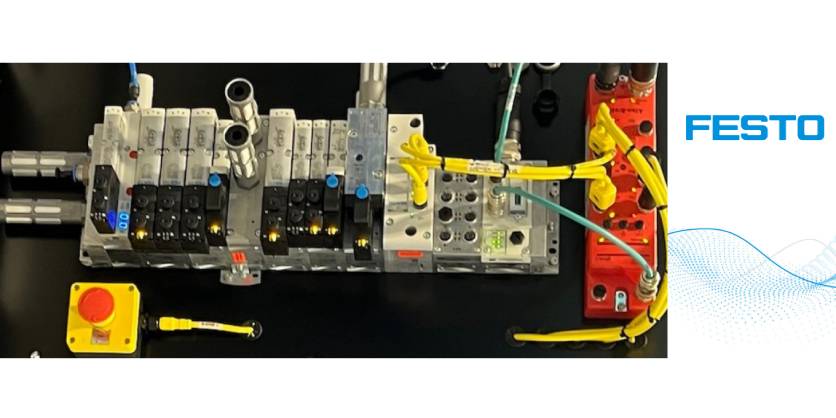

Festo introduces an innovative suite of safety products, including its new CIP safety module, that ensures the safe operation of pneumatic systems and lowers the risk of injury and system and product damage.

Festo pneumatic safety solutions are compatible with the top industrial Ethernet protocols – EtherNET/IP, PROFITNET, and EtherCAT – which gives them near universal application.

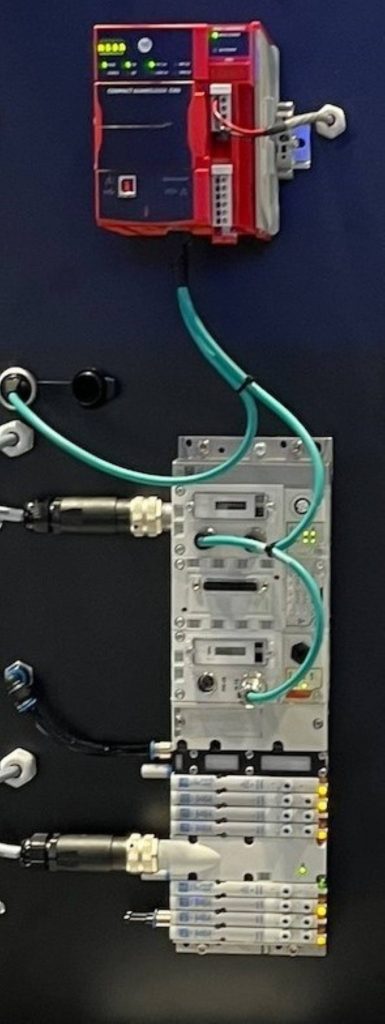

The new CIP safety module connects directly to the safety controller, with no need for a safety I/O block, which simplifies wiring and can reduce cost by eliminating the requirement for separate safety I/O. The safety module offers one safe zone for up to a CAT4, Ple, and SIL3 safety level for safety sub-functions: safe-switch-off and prevented-unexpected startup.

The CIP safety module can also work with an integrated pilot air control valve for redundant shut-down of directional valves and an integrated pressure sensor to monitor pilot air. These are compatible with the Festo MPA-S and VTSA valve terminals. The CIP Safety module will be available in 2025.

Three additional safety solutions in the suite

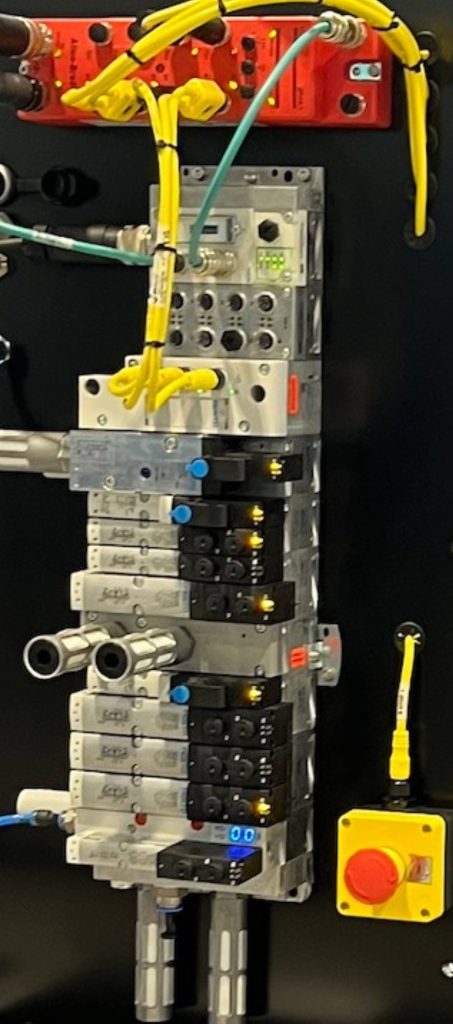

Festo’s new flagship valve terminal, the VTUX, has been designed with safety in mind. VTUX valves feature negative overlap spools that allow for safe exhausting of compressed air in case a valve spool is in an indeterminate position. Festo will be incorporating additional safety features as the platform matures.

For those in the automotive industry that use safe I/O blocks, such as Allen-Bradley ArmorBlock Guard I/O modules, Festo offers its CPX platform with VTSA-F-CB valve terminal. This solution delivers three safe zones controlled by an external safety controller. The VTSA-F-CB offers up to a CAT3, Ple, and SIL3 safety level for safe-switch-off and prevented-unexpected startup. It also offers soft start/quick exhaust options.

For those applications outside the automotive industry that use safe I/O blocks, the MPA-S can also support safe zones with power supply modules, a soft start/quick exhaust option, and pilot air control valves. This valve terminal solution offers up to a CAT2, Pld, and SIL2 safety level for safe-switch-off and prevented-unexpected startup.

Festo’s new Automation Platform (AP) CPX-AP-A provides I/O and interfaces to valves terminals VTSA, MPA-S, and VTUX. The backplane performance of this new system can handle modern requirements for speed, capacity, security, and safety. The CPX-AP-A can also run in a hybrid mode that allows for remote and distributed valves and I/O.

With either the CPX or the CPX-AP-A, safety with valve terminals can be supported. Either system can monitor both pilot air pressure and voltage of each safe zone, and can provide feedback data used with safe instructions within the safety PLC.

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For more than 50 years in the U.S., Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment. Through advanced technical and industrial education, Festo Didactic Learning Systems and its partners prepare workers for current and future manufacturing technologies.

More Information

For more information on these safety products, contact Festo. And for information on the advantages of working within the Festo ecosystem of less engineering overhead, fast time to market, seamless connectivity, and the industry’s widest selection of electric and pneumatic automation components, visit www.festo.com

Related Story

New Festo Canada Program Helps End Users Find System Integrators for Automation Projects

For end users wanting to incorporate more automation in their operations but lacking the in-house capability to make it happen, Festo Canada has a solution to overcome that barrier. The company’s new Certified System Integrator Program will match an end user with highly skilled system integrators, providing the validated know-how and expertise to turn the aspirational into the realizable.