Festo Introduces ELGD, a New Generation of Electric Actuator for Linear Applications

May 2, 2024

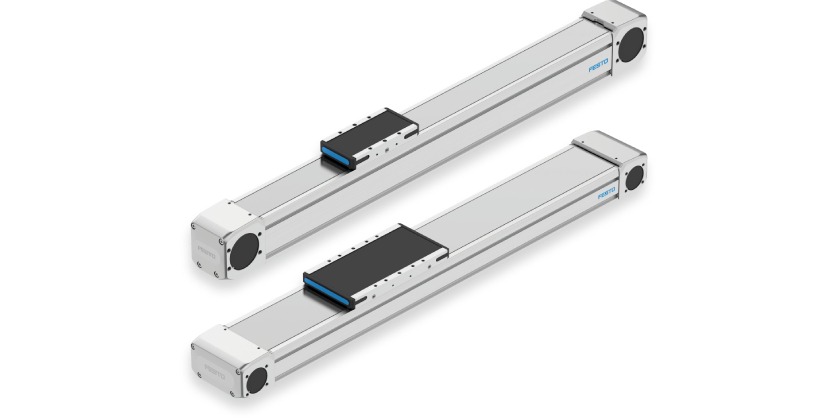

Festo introduces its newest generation of electrical Cartesian-handling-system mechanical axes. The ELGD-TB tooth belt actuators, and ELGD-BS ball screw actuators, are based on an innovative Festo design.

Festo inlaid the bearings into the aluminum extrusion and extended bearings to the full width of the axis. This design enhancement enables high loads in a compact footprint. Machine builders can pack even more powerful tooth belt or ball screw axes in smaller footprint systems to achieve excellent feed forces and acceleration profiles.

The integrated bearing design also enabled Festo to develop the lower profile ELGD-WD (wide actuator) for reduced force applications. This low-profile ELGD is 30% lighter than larger units while its rigidity and guide load capacity are similar.

The ELGD-BS ball screw drive offers configurable stroke lengths up to 8.2 ft. The ELGD-TB toothed belt drive provides stroke lengths of up to 27.9 ft. The ELGD series gives a choice of carriage options, including a long carriage and additional passive carriage. The long carriage integrates a second pair of split ball bearing cartridges,

which provides even greater permissible torques to the carriage for the most dynamic applications. The passive second carriage allows the loads on the guidance to be distributed even further, essentially doubling the maximum permissible torques, load capacity, and service life for the mechanics in the application.

Suited to most electromechanical handling tasks, ELGD axes deliver exceptional load bearing capacity and torsional rigidity, long service life, and increased reliability in multiple industrial handling situations, from dirty to cleanroom environments.

The ELGD can enhance many applications, for example:

- Cantilever systems and pick-and-place solutions for small parts handling, where short cycle times, high precision, and repeatability are key

- Handling systems for top loaders, which benefit from the ELGD’s attractive price/performance ratio, high travel speed, and long stroke lengths

- Automation of 3D printing, additive manufacturing, dosing, gluing, and picking and placing are enhanced with the ELGD’s dynamic, virtually vibration-free movement.

With the Festo Electric Motion Sizing online productivity tool, design engineers input application parameters and the tool finds the right combination of CMMT multi-protocol servo drive, Festo servo or stepper motor, and accessories for the axis with all components perfectly sized and interoperable.

Festo’s start-to-finish management of every aspect of the ELGD series design, testing, and manufacture ensures world-class quality, a robust and reliable supply chain for assured availability, and industry leading price/performance.

Related Story

Festo Sees Good Growth Prospects

After years of strong growth, 2023 was a year of consolidation. Turnover was just below the previous year’s level (- 4.3% to around 3.65 billion euros). Festo continued to invest heavily in research and development and the expansion of regional market supply. The company sees good opportunities for growth again in the medium term. The automation of future markets, but also the qualification of the specialists required for this, offers Festo great potential for sustainable growth in the Automation and Didactic business. This includes segments such as battery and electric vehicles, green hydrogen and the semicon industry.