Festo Introduces DHPL, a Competitively Priced Long-Stroke Parallel Gripper

January 9, 2024

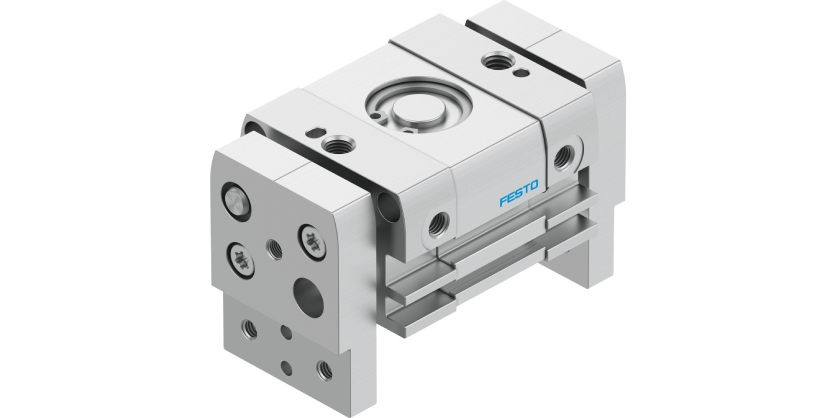

The new DHPL delivers high load and torque parallel gripping in a light, compact body

From recently completed production lines, Festo introduces the DHPL, a new generation of competitively priced long-stroke grippers that offers a host of advantages for high load and torque applications. The DHPL is interchangeable with competitive long-stroke grippers. It provides the added benefits of lighter weight, higher precision, and no maintenance. The new long-stroke gripper is ideal for stacking boxes, gripping plates and shaped parts, and keeping bags open.

The long-stroke DHPL parallel gripper features ≤ 0.03 mm repetition accuracy due to three rugged guide rods and a rack and pinion design. Even though these units are light and compact and suitable for today’s smaller footprint machine, the DHPL delivers high load and torque grip. Force ratings range from 40 N to 750 N. Jaw stroke ranges from 20 mm to 200 mm.

This gripper gives machine builders and end-use customers flexibility in mounting options and sensor placement. Positioning pin holes ensure the DHPL gripper mounts in the precise position of the gripper it replaces. Jaw interfaces allow for fingers and brackets to be added. Fingers and brackets enable the perfect grip for the part. Pneumatic end-position cushioning is standard and can be adjusted for optimal performance according to the moving mass and speed.

About Festo

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. Celebrating 50 years in the U.S., Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment. Through advanced technical and industrial education, Festo Didactic Learning Systems and its partners prepare workers for current and future manufacturing technologies.

More Information

For more information on the new grippers and the advantages of working within the Festo ecosystem ‒ the ecosystem that leads to less engineering overhead, fast time to market, and seamless connectivity ‒ visit www.festo.com.

Related Product

Festo Launches HPPF Diminutive Flat Parallel Gripper for Space-Constrained Applications

Thanks to manufacturing innovations achieved on a new production line, Festo’s HPPF diminutive flat parallel gripper not only delivers great force in tight spaces, it’s also extremely well-priced. HPPF ranges from 19 mm to 41 mm among its four sizes: 8, 12, 16, and 20. The stroke ranges from a narrow 8 mm to a wide 80 mm, with gripping forces from 60 N to 377 N. These specs make the new HPPF ideal for space-constrained applications in small parts and electronics assembly. That includes battery manufacturing, since each HPPF contains less than 1% copper/zinc/nickel.