Festo AX Controls Automation Portfolio as a Platform for Many Software Apps

November 19, 2024

More customer success through seamless data accessibility

Users today face the challenge of having to integrate different topics such as control and motion, AI, data integration and evaluation, predictive maintenance and much more into their applications at the same time, with short development cycles and ever new requirements. Festo AX Controls presents an automation portfolio that takes these requirements into account. The motto “from the workpiece to the cloud” is taken further here, and Festo AX Controls combines many software modules such as operating system, motion, visualization, high-level languages and low-code through to commissioning software with a scalable hardware platform.

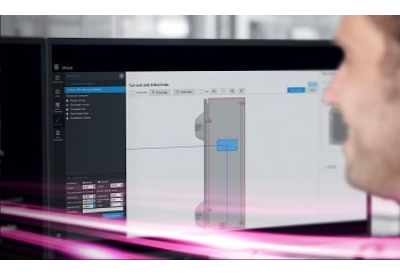

Festo AX Controls consists of the Festo AX OS (Operating System), the Festo AX Motion control software, the Festo AX Machine Visualization software and the first edge controller CEPE. This creates a flexible solution portfolio for industrial control tasks. Fields of application can be developed from the classic motion controller to a wide range of motion, IoT and edge tasks in the industrial environment, depending on customer requirements.

Common basis and open architecture for more benefits

Festo AX OS is based on PLCnext technology from Phoenix Contact, which was developed for industrial environments. This enables real-time applications, programming with modern programming languages and seamless cloud connectivity. The containerized runtime environment enables an open and modular software architecture and the integration of modern AI-based software. Cybersecurity requirements were already integrated during development. This creates the basis for accessing, evaluating, archiving and reusing valuable process data.

Festo AX Controls makes use of these advantages: users can develop individual solutions and seamlessly integrate existing systems to meet the requirements of various industrial applications. The efficiency of the development processes can also be increased through the use of open source software and apps – there are no limits to future extensions.

Powerful and communicative hardware

CEPE, the first edge device on Festo AX OS, is now also available for executing software modules at runtime. Equipped as standard with an Intel i3 processor and a wide range of communication interfaces such as EtherCAT or Festo’s own AP master, the CEPE edge controller can be optimally connected to different control architectures: It seamlessly integrates Festo’s entire electrical and pneumatic portfolio so that customers can always use the right technology for their application. The CEPE’s industry-proven hardware with its open control architecture thus offers many development options for different software applications.

Many apps accessible

As a first step, Festo is already providing a large number of different software apps. CODESYS is a leading automation software for configuring control systems. Customers also have the option of programming automation tasks in high-level languages with a Python app.

Customers can also use Festo AX Industrial Intelligence, a powerful AI tool from Festo for predictive maintenance to increase system availability. All of these software apps and licenses will be available via the Festo online catalog. As part of the PLCnext Technology ecosystem, it will also be possible to purchase software from the growing PLCnext Store in the future.

Overcoming challenges together

The combination of Festo and Phoenix Contact’s expertise enables profitable cooperation in order to master the technological challenges of digital transformation or cybersecurity, for example. The common goal of Festo and Phoenix Contact is to meet the requirements resulting from the convergence of IT and OT (Information Technology and Operations Technology) in the industry through open automation solutions.

About PLCnext Technology:

PLCnext Technology is the open ecosystem for industrial automation from Phoenix Contact. With its combination of open control technology, modular engineering software and online community, this solution enables easy adaptation to changing requirements and efficient use of existing and future software services. Together with a digital marketplace for software and systemic cloud integration, PLCnext Technology is up to the challenges of the IoT world.

Festo at a Glance

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries.

Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries. With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.65 billion in 2023. Each year around 7% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.

Related Story

New Festo Canada Program Helps End Users Find System Integrators for Automation Projects

For end users wanting to incorporate more automation in their operations but lacking the in-house capability to make it happen, Festo Canada has a solution to overcome that barrier. The company’s new Certified System Integrator Program will match an end user with highly skilled system integrators, providing the validated know-how and expertise to turn the aspirational into the realizable.