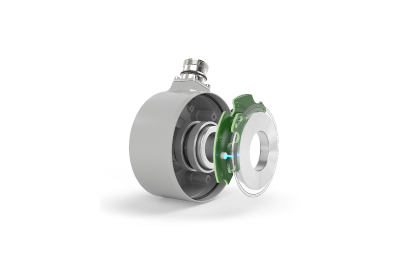

ENI90 Series Incremental Rotary Encoders—Unique Precision with BlueBeam Technology

May 31, 2022

Asynchronous motors or generators require high-precision speed control. For such applications, Pepperl+Fuchs has expanded its portfolio of hollow shaft rotary encoders with the ENI90 series. With integrated BlueBeam technology, these compact and robust incremental rotary encoders bring maximum precision to any standard or heavy-duty application, and can withstand rotational speeds of up to 6,000 rpm due to strong shock resistance. For speed control, scanning is performed with blue LED light. Compared to infrared light, this achieves the highest signal quality currently available, the best efficiency and a very high resolution.

The ENI90 product family is available in three different versions with a comprehensive range of accessories to meet the requirements of a wide variety of applications.

Three Variants for Maximum Application Diversity

The portfolio of ENI90 rotary encoders includes three different variants with individual configuration options:

The ENI90IL series provides users with an economical rotary encoder solution that is ideal for standard applications.

The ENI90PL rotary encoders are used, for instance, on electric motors and generators, or wherever precise speed determination is required. They demonstrate their precision even in demanding environmental conditions: the rotary encoders feature an insulated drive shaft for high dielectric strengths of up to 2 kV, high shock and vibration resistance, and EMC circuit protection that ensures maximum system availability.

As a robust heavy-duty rotary encoder, the ENI90HD delivers maximum performance even under the most challenging environmental and operating conditions. The combination of a rugged design, a high mechanical load capacity, and a peak dielectric strength of up to 2.5 kV ensures long-lasting reliable operation in steel mills, including the lifting and conveying technology. The ENI90HO rotary encoder, the offshore variantof the heavy-duty rotary encoder, is specifically designed for use in offshore applications, e.g. on oil rigs, in port facilities or in offshore wind farms.

High Mounting Flexibility and Extensive Accessories

Due to standard tapped holes in 60° increments, all three variants of the ENI90 family offer high mounting flexibility. Extensive accessories, including swivel arms, spring and support plates for connecting the rotary encoders to the application, seal inserts for cable bushings, and grounding kits, expand the range of uses for the ENI90 series and facilitate integration into the application.

Highlights of the ENI90 Rotary Encoder Family

- •Unique precision achieved by BlueBeam technology—whether in standard or heavy-duty applications

- •Rotary encoder series with a rugged, compact housing design and high environmental protection for use in demanding industrial environments

- •Durable due to high shock and vibration resistance even at speeds up to 6,000 rpm

- •Utmost mounting flexibility due to tapped holes in 60° increments and wide variety of accessories

To learn more about the ENI90 series of rotary encoders from Pepperl+Fuchs, click here