Energy-Efficient and Smart: Sytronix Variable-Speed Pump Drives

Sept 17, 2019

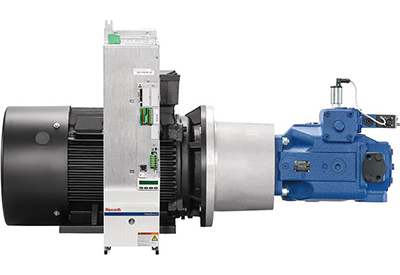

Where fluctuating power demand is thrown into the mix or single-axis solutions are implemented, designers are increasingly turning to Rexroth’s Sytronix variable-speed pump drives. Depending on the proportion of partial load, they can reduce the power consumption of hydraulics by up to 80%. At the same time, system manufacturers can turn functions, which were previously carried out hydromechanically, over to the software and thus significantly increase the flexibility of their systems.

Energy efficiency is also a megatrend for end users in metallurgy and has a significant impact on operating costs. Variable-speed pump drives can directly reduce power consumption even for installed pre-existing systems as they reduce speeds in line with demand.

Rexroth’s Sytronix variable-speed pump drives also provide the freedom to adopt completely new design approaches. Numerous hydraulic functions for power units and axis control are already integrated in the software of the controllers. As compact axes they directly drive a cylinder. In multi-axis solutions, the axes are synchronized via the multi-Ethernet interface with popular real-time Ethernet protocols. End users can change the motion sequences in these solutions with a simple mouse click. Designers can create a hydraulic gear in connection with adjustable axial piston pumps. This enables them to downsize the drive system and reduce both power consumption and the amount of space required. Intelligently connected Sytronix drive systems also cover higher performance ranges as part of master-slave solutions.

A customized system in less than 30 minutes

Rexroth is able to simplify the dimensioning, configuration and ordering of smart Sytronix products with a closed tool chain. The dimensioning tool SytronixSize intuitively guides users through the digital design process. It combines the data of the hydraulic and electrical individual components based on models. In the background, Rexroth’s know-how, which has been converted into software, optimizes the solution. The software automatically checks the components’ thermal load capacities and displays the energy savings and average noise emissions. Designers then determine the properties of all the components in the drive train. Ultimately, users receive a parts list (which has been checked in terms of completeness), the documentation and the 3D-CAD data.

Users can then access the Rexroth e-shop with a simple mouse click. The e-shop adopts the configured customized solution and provides the registered customer with the price and the expected delivery date. Rexroth is able to reduce the digital engineering time required for a customized Sytronix solution, optimized in line with the intended application, to less than 30 minutes on account of the closed tool chain.

Go HERE for more information