Emerson Next-Generation Pneumatic Valves Now Available With Higher Flow Rates, Greater Flexibility

March 11, 2025

The latest AVENTICS Series XV release offers greater range with new flow rates, configurations, functionality, certifications and more.

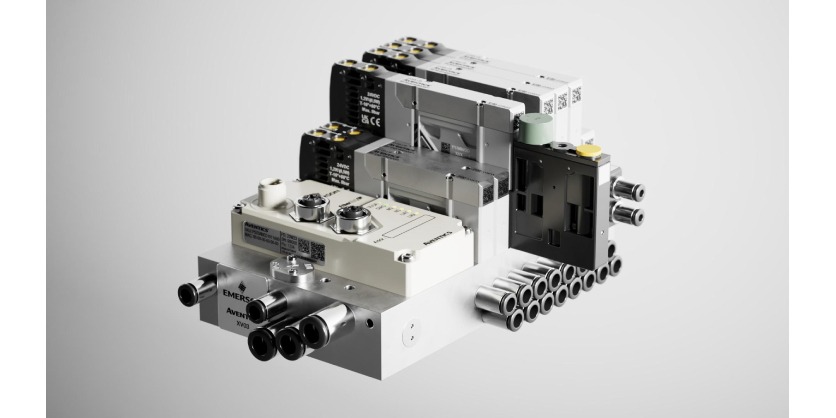

Emerson has released the latest stage of its next-generation AVENTICS™ Series XV pneumatic valve systems with new flow rates, configurations, accessories, UL certifications and more. These updates give original equipment manufacturers (OEMs) greater design flexibility and scalability to precisely configure valves when engineering handling systems and automation solutions.

After successfully launching the AVENTICS Series XV03 in most world regions in July, Emerson has now released the popular XV03 valve for U.S. markets, as well as globally released the larger Series XV05 and a bottom-ported version of the XV03. The XV03 provides flow volumes up to 350 liters per minute in normal conditions (NL/min), and the XV05 provides up to 1000 NL/min.

In addition to new flow rates and configurations, Series XV valves are also available with UL certifications and more accessories. Both the XV03 and XV05 are designed for compliance with UL429 and UL61010 for quality and safety. New and existing accessories provide greater functionality and include separators, blank stations, pressure supply plates, sandwich pressure supply, and sandwich pressure exhaust. There is also a custom toolbox that contains the most important tools to assemble XV systems.

The next phase of the staged XV release will see the continued launch of new accessories as they become available, as well as greater connectivity. Additional fieldbus protocols will be launched throughout 2025, including Powerlink, CanOpen in mid-2025 and AS-I in late 2025. The valve systems currently support Profinet, Ethernet/IP, EtherCAT, Modbus TCP, Profibus DP and IO-Link.

Next-generation Series XV valves use proven core valve AVENTICS technology and include metal threads, aluminum base plates and compact dimensions to make integration easier. Complete valve systems are easy to commission with the AVENTICS online configurator that streamlines design and layout. To reduce lead times for every global region, three Emerson plants are equipped to manufacture orders.

Providing higher flow rates in a compact valve package, Series XV valves enable more efficient and flexible pneumatic system performance while offering products customized for specific markets, including factory automation, automotive and tire, food and packaging applications. Part of a Floor to CloudTM approach, Series XV valves power machinery and processes at a component level, helping manufacturers boost productivity in applications.

More Information

For more information about AVENTICS Series XV pneumatic valve specifications, features and resources, please visit the website or configure the valve here.

Related Story

Emerson Showcased Packaging Solutions that Advance Future of Automation at PACK EXPO 2024

Global technology, software and engineering leader Emerson exhibited its latest Floor to CloudTM packaging solutions at PACK EXPO Chicago, November 3-6, 2024. Advancing the boundless future of automation, Emerson factory automation solutions and its Floor to Cloud approach empower smarter packaging lines and more efficient processes that make it possible for manufacturers to continuously improve plant productivity, sustainability and safety.