Emerson Introduces Healthcare Industry’s First Integrated Manifold Solution for Respiratory Therapy Devices, they Claim

The ASCO Series 588 manifold reduces manufacturer engineering and assembly time, improves energy efficiency, product lifespan and reliability of devices

August 8, 2023

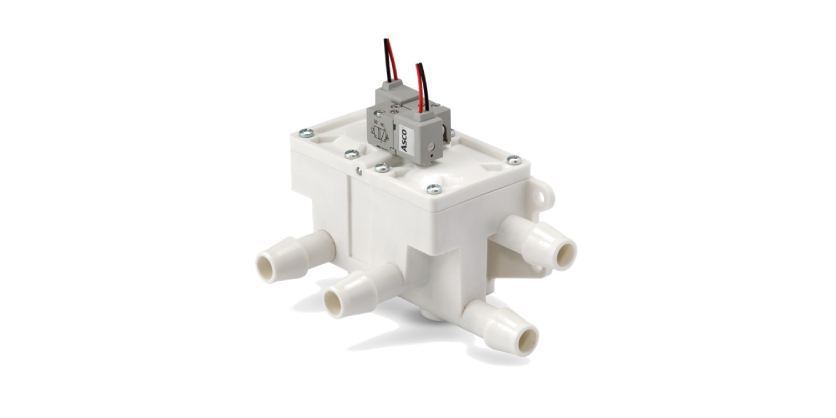

Emerson has launched the ASCO™ Series 588 Stationary Oxygen Concentrator Manifold, what they claim to be the healthcare industry’s first turnkey manifold solution designed to optimize respiratory therapy device designs and accelerate product speed to market. Oxygen concentrators must quickly reach patients who rely on them, so it’s critical that they are readily available and operate reliably. The Series 588 manifold is specially designed to simplify device engineering and assembly and improve device energy efficiency, lifespan and reliability.

Without an integrated manifold, manufacturers must mount valves individually into the fluidic path of oxygen concentrators and attach dedicated tubing to each orifice. Alternatively, the small, lightweight architecture of the Series 588 manifold easily integrates into the fluidic path of oxygen concentrators, significantly reducing engineering and assembly time for medical equipment manufacturers. The Series 588 features two robust general service valves that precisely control the flow of air between the compressor and the sieves. The manifold fastens easily into the fluidic path, and a barbed port design makes it simple to connect tubing.

“Oxygen concentrators are essential to the health and well-being of patients with chronic respiratory disorders, so it is critical they are readily available for therapy. However, one of the most important aspects of these devices is an intelligently designed fluidic path, and that takes time,” said Thomas Beck, product marketing manager for analytical and medical at Emerson. “With the ASCO Series 588 Manifold, our fluidic path experts have designed a low-power, robust solution that can save medical manufacturers time and lifetime costs. Manufacturers can quickly and simply install the integrated manifold by connecting just a few tubes.”

Thomas Beck, product marketing manager for analytical and medical at Emerson

In addition to simplifying design and assembly, the Series 588 can help improve device energy efficiency and reliability while lengthening product life. The manifold’s compact footprint can enable smaller device designs without sacrificing performance. The valves’ low power demand can extend device battery life and time between charges, which can set a manufacturer’s product apart from competitor offerings. And the high reliability of the valves can lengthen the overall lifespan of the oxygen concentrator and minimize manufacturer lifetime costs.

More Information

ASCO 588 Stationary Oxygen Concentrator Manifold

Related Product

Emerson To Unveil New Approach to Discrete Automation at Hannover Messe 2023 (Hall 6, Stand C57)

Emerson will exhibit advanced, discrete automation solutions, from the factory floor to the cloud, at Hannover Messe. Visitors to Hall 6, Stand C57 can view the Discrete Automation portfolio of ASCO™, AVENTICS™, Branson™, Movicon™, PACEdge and PACSystems™, as well as CoreTigo solutions. Emerson experts will show attendees how to access and harness critical data of their machines, production lines or their full production plant. Through live demonstrations and visioning sessions, visitors will learn how using these technologies to get essential insights will help them drive continuous improvement throughout their operations and make processes more productive, smarter and more sustainable.