Emerson Introduces First Pneumatic Valve System with Integrated Open Platform Communications Unified Architecture

June 6, 2022

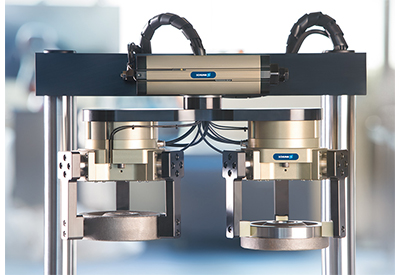

Recently, Emerson announced that its AVENTICS™ Series Advanced Valve (AV) valve system with Advanced Electronic System (AES) Profinet and Ethernet/IP is now available with preinstalled Open Platform Communications Unified Architecture (OPC UA) functionality, allegedly making it the first and only valve system to offer this directly integrated capability. The AES helps users solve interoperability challenges and access data more easily while the integration of the digital twin can improve productivity and efficiency.

A valve system with integrated OPC UA functionality simplifies communication with upper systems since data and analytics are received via the valve system and communicated directly to upper systems, no gateway necessary unless deeper analysis or local dashboards are required. This can result in costs savings for users since it’s more complex and expensive to receive analytics from a valve system without OPC UA.

OPC UA functionality also expands the connected capabilities of the valve system itself, making it easier for users in industries such as automotive, food and beverage, packaging, pulp and paper industries and more to digitally transform. When organizations undergo digital transformation, key protocols such as OPC UA embedded in technologies enable device monitoring and machine connectivity when sending data from a valve system to an upper system. The AES is simple to integrate and connect to new or existing applications and machines and provides easy access to data and analytics without changing the programmable logic controller (PLC).

“The AVENTICS Series AV System with OPC UA is a notable leap forward in the flexibility and integration of valve systems because it makes the transition to IIoT significantly simpler for engineers,” said Nils Beckmann, senior manager of product marketing, IIoT at Emerson. “With OPC UA, engineers don’t need to change a whole system or architecture to access valve data. They now have the flexibility to continue using their own cloud systems and software to gain easy access to data and analytics without disrupting or modifying the PLC.”

Developed by the OPC Foundation, OPC UA is a platform independent, information technology standard for sensor-to-cloud data exchange that features integrated security.

For more information about the AVENTICS™ Series Advanced Valve (AV) valve system from Emerson, click here