Emerson Improves Device and Process Visibility with FieldComm Group Registration

March 15, 2022

Emerson, a global software, technology, and engineering leader, recently announced that its device management software is the first host software to be fully registered by FieldComm Group® to support the Field Device Integration (FDI) standard. This is a further step in Emerson’s ongoing efforts to reduce the time and effort spent installing and configuring the field devices plants rely on to achieve their digital transformation goals.

AMS Device Manager is the first software of its kind to be registered under the Field Device Integration standard, making it easier to monitor and optimize plant health

Field devices collect and transmit important data that personnel use to improve plant health, performance, and reliability. FDI registration will reduce the need for plants to support two different technologies to integrate and maintain field devices. Full FDI registration is important to avoid having a patchwork of systems and devices that only support individual elements of FDI but still require extensive integration effort. Because manufacturers can pick and choose individual FDI features to support, some device management applications will likely not contain every feature a plant requires. Emerson worked side by side with FieldComm Group for nearly two years to enable AMS Device Manager to pass the group’s rigorous testing process for registration, which requires all features to be supported by the software.

“Today’s intelligent field devices offer a broad range of data and functionality that plant personnel can use to optimize operations, but without a common standard, collecting that data can be complex and cumbersome,” said Ted Masters, chief executive officer of FieldComm Group. “By completing the process to fully register AMS Device Manager’s FDI support, Emerson is providing its customers the tools to more easily implement a wider range of devices for holistic plant health.”

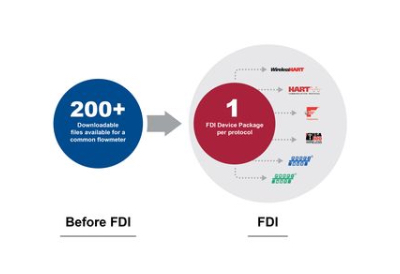

The newest release of AMS Device Manager will make it easier, more secure, and more cost effective to access device data. FDI integration technology eliminates the need for plants to support the two most common technologies for installing and configuring devices: Electronic Device Description Language (EDDL) and Field Device Tool/Device Type Manager (FDT/DTM). Instead, all FDI devices support a single installation package, so organizations will no longer have to double up on time, training, and effort when installing field devices.

“FDI integration technology takes the best features of EDDL and FDT/DTM and combines them into a single common standard, making it far easier to select, install, configure, and support new devices,” said Erik Lindhjem, vice president of Emerson’s reliability solutions business. “By adding full FDI registration to AMS Device Manager, Emerson continues its tradition of supporting and innovating on industry standards to help organizations drive more value from digital transformation initiatives.”

For more information about the AMS Device Manager, click here

For more information on FDI, click here