Making Drilling More Efficient for New Carbon Capture, Usage, and Storage Facilities

August 8, 2024

Drillmec’s innovative storage technologies make drilling entry points for new carbon capture, usage, and storage (CCUS) facilities faster, easier, safer, and more cost effective

With help from Rockwell Automation, Italian drilling-rig specialist Drillmec is using data-driven and precision automation for maximum efficiency and minimum emissions.

Drillmec’s innovative storage technologies make drilling entry points for new carbon capture, usage, and storage (CCUS) facilities faster, easier, safer, and more cost effective. This initiative underpins Drillmec’s drive to develop solutions that draw on its drilling and rig expertise to reduce emissions and achieve environmental goals.

CCUS initiatives involve trapping carbon at the point of emission – for example, in a factory – and then pumping it to a suitable underground storage facility where it is permanently stored, preventing it from being released into the atmosphere.

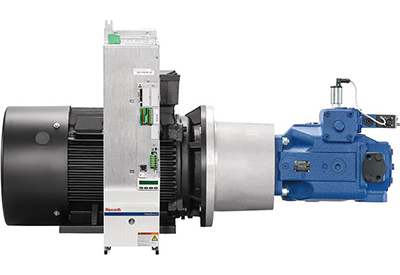

Drillmec’s technology, relying on Rockwell’s PowerFlex® AC drives, is able to be more precise and targeted when creating entry points for drilling. This extra efficiency helps to lower the barrier to entry for new CCUS facilities. This not only helps to lower costs it has the potential to significantly lower emissions related to a range of industrial and domestic uses. As well as providing technology, Rockwell has been working closely with Drillmec to optimize the drilling workflow for maximum efficiency and minimum emissions.

“We are excited to be bringing to market this new drilling technology, specifically designed to enable the development of carbon capture and storage sites,” said Mohamed Housny, vice president of marketing at Drillmec. “Rockwell Automation technology and expertise has been central to achieving the intelligence, precision and control required for the new technology to be a success. We look forward to continuing to work with Rockwell Automation on this and future projects.”

More Information

Learn more about Rockwell’s solutions for the oil and gas industry.

Related Story

Rockwell Automation Expands Application Coverage with Permanent Magnet Motors and Extends Device Analytics in Medium Voltage PowerFlex VFDs

The latest firmware release for PowerFlex® 6000T medium voltage variable frequency drive (VFD) now supports efficient permanent magnet (PM) motor applications. As manufacturers in the oil, gas, HVAC, paper, water, metals and forestry industries aim for new energy efficiency and sustainability goals with PM motor solutions, the PowerFlex VFD supports high-speed applications up to 120 Hz output frequency, from 2.3…11 kV up to 680 A.