Distributed Drive Systems for Control Cabinet-Free Machine Concepts

January 23, 2025

What is distributed drive technology?

In recent years, distributed drive technology has become a key part of automation and drive technology. It offers significant advantages over traditional centralized approaches, especially in terms of flexibility, scalability, and efficiency. Distributed drive technology moves drive components, such as servo drives or stepper motor terminals, out of the control cabinet and into the machine.

In contrast to centralized drive technology, in which all control and regulation components are housed in a central control cabinet, the components involved in distributed drive technology are installed directly in the housing of the motor.

Your head start with distributed drive systems from Beckhoff:

- control cabinet-free concepts

- space-saving, straightforward, and smaller footprint

- reduced material and labor costs

- simple wiring and low installation and commissioning costs

- EtherCAT system

- high level of modularity for system adaptations or extensions

- connection of additional I/O signals in IP65 configurations possible

The technology behind distributed drive technology

Distributed servo drive system

AMP8000 | Distributed servo drive system

- Power

- distributed servo drive: up to 2.6 kW

- distributed power supply module: 11 kW

- Standstill torque up to 11.8 Nm

- Voltage range

- 1 x 120…240 V AC

- 3 x 200…480 V AC

- Wiring

- Star wiring

- OCA wiring

- Safety

- TwinSAFE STO/SS1 or TwinSAFE Safe Motion

- via FSoE (FailSafe over EtherCAT)

- integrated TwinSAFE Logic

- Sizes

- F3, F4, F5

- Special features

- available with holding brake and additional inertia

Integrated servo drives

AMI8100 | Compact, integrated servo drives

- Power up to 0.35 kW

- Standstill torque up to 2.85 Nm

- Voltage range up to 48 V DC

- Wiring

- Daisy-chain wiring and star wiring possible

- Safety

- TwinSAFE STO/SS1

- via FSoE (FailSafe over EtherCAT)

- integrated TwinSAFE Logic

- Sizes

- F2, F3

- Special features

- two additional I/Os for drive-related functions with a voltage of 24 V DC

- integrated travel path control: direct control without NC possible via MDP protocol

- Operation on third-party masters is possible with DS402 protocol.

- available with holding brake

Integrated stepper motor drives

ASI8100 | Compact, integrated stepper motor drives

- Power up to 0.25 kW

- Holding torque up to 2.5 Nm

- Voltage range up to 48 V DC

- Wiring

- Daisy-chain wiring and star wiring possible

- No safety

- Sizes

- NEMA 17, NEMA 23 (in preparation)

- Special features

- two additional I/Os for drive-related functions with a voltage of 24 V DC

- integrated travel path control: direct control without NC possible via MDP protocol

- Operation on third-party masters is possible with DS402 protocol.

Accessories

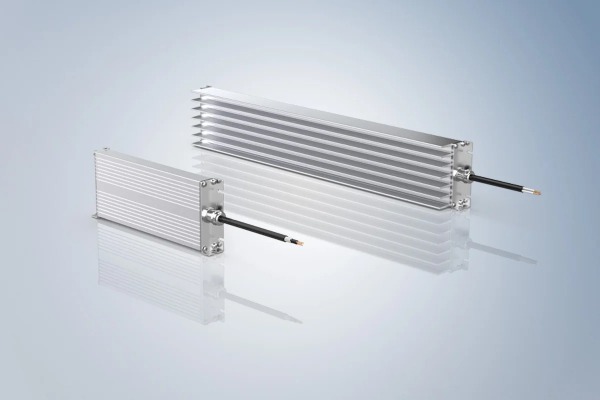

- Braking resistors

- AX2090-BW65 | External braking resistors for AMP8000

- EP9576-1032 | EtherCAT Box, brake chopper box for AMI8100 and ASI8100

- Power distribution

- ZS2030-4812 | T splitter for AMI8100 and ASI8100

- EP9208-1035 | Passive power distribution box for AMI8100 and ASI8100

- Pre-assembled cables

- Hybrid cables for AMP8000

- EtherCAT and fieldbus cables for AMI8100 and ASI8100

- Power cables for AMI8100 and ASI8100

- Sensor cables for AMI8100 and ASI8100

- Hybrid connector accessories for AMP8000

Beckhoff in action

Borghi S.p.A.

The new production sequence developed by the Italian machine builder Borghi S.p.A. created a striking increase in productivity and was implemented with PC-based control and the AMP8000 distributed servo drive system based on EtherCAT P. Learn more

URBX

Compact, powerful control technology for AGVs and mobile robots. Storage racks up to 125 feet tall. Totes weighing 100 pounds. And no tedious searching for SKUs. US company URBX has developed a new high-speed fulfillment solution for retail stores and e-commerce. Automation technologies from Beckhoff provide the reliable foundation for this. Learn more

Syntegon Technology GmbH

Syntegon, a global supplier of process and packaging technology for the food and pharmaceutical industries,has designed the new end-of-line cartoner as an entry-level machine and recently equipped it with AMP8000 distributed servo drives rather than mechanical drive technology. According to Pete Hyde, electrical and software engineering manager at Syntegon, this is a key requirement for stable processes: “Switching to servo technology allows us to perfectly synchronize different drive components, securing repeatable product placement. The flexibility and reliability that this achieves are key to the success of our equipment.” Learn more

Classic Car House

A lovingly restored 1965 Citroën 2CV stands on a pedestal. Suddenly, the scene comes to life as a series of pulleys allow the individual parts of this iconic car to float up to the ceiling and back down as if by magic. Designed by Kvorning Design and delivered by All Stage Production, this installation is the latest attraction at the Classic Car House in Copenhagen. And what is it that ensures this crowd-pleaser functions precisely, reliably, and safely? PC-based control from Beckhoff. Learn more

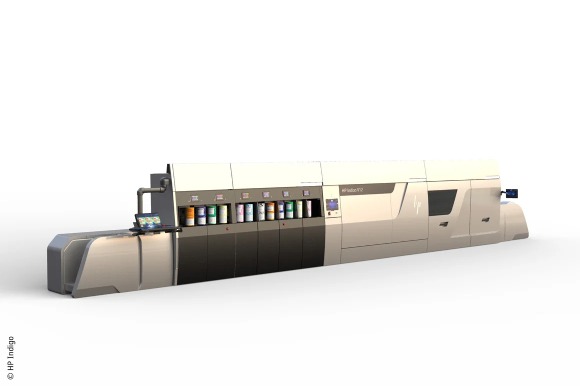

HP Indigo

Shorter product life cycles and increasing customization are changing many areas of life, and the packaging market is no exception. Accordingly, manufacturers increasingly need to adapt both the shape and the look of their products to their customers’ requirements, even for smaller quantities – right down to a lot size of one. Israel-based printing specialist HP Indigo accommodates these changes with its new V12 digital printing press, in which roughly 100 axes are precisely synchronized and rapidly controlled with PC-based control technology, EtherCAT, and compact, integrated AMI812x servo drives. Learn more

More information

AMP8000 | Distributed servo drive system

Synchronous servomotor with integrated servo drive for control cabinet-free modular machine concepts. Learn more

AMI8100 | Compact integrated servo drives

Synchronous servomotor with integrated servo drive for the realization of machine concepts without a control cabinet in the low voltage range. Learn more

ASI8100 | Compact, integrated stepper motor drives

Stepper motors with an integrated stepper motor output stage for low-voltage control cabinet-free machinery concepts. Learn more

OCA | One Cable Automation

One Cable Automation facilitates efficient and optimal cabling for devices, machines, and systems. Learn more

Related Story

Beckhoff Future-Proofs Hybrid Connectors in Industrial Cable Offering

Beckhoff’s proven hybrid connectors, part of the company’s One Cable Automation (OCA) solution, are receiving a major update to better support distributed automation well into the future. Beyond the design advantages of consistent modularization with a uniform data core, these connectors now comply with the upcoming IEC 61076-2-118 standard, enabling a seamless transition in advance of the rollout.