Danfoss: VACON® 100 INDUSTRIAL

- 208-240 V…0.55-90 kW

- 380-500 V…1.1-630 kW

- 525-690 V…5.5-800 kW

Features and benefits:

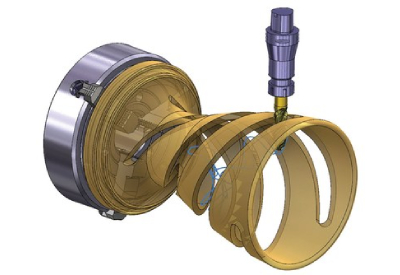

- Easy integration with plant automation due to extensive range of fieldbus options

- High reliability in challenging environments as a result of conformal coating

- Extended drive lifetime thanks to film capacitors

- No additional accessories are required due to integrated RFI filters and DC choke

For more information, visit https://www.danfoss.com/en/products/ac-drives/dds/vacon-100-industrial/#tab-overview